Many believe modern generators don’t need a break-in or that running them at full load right away is fine, but that’s incorrect. Proper planning involves gradual load application, warm-up, and following manufacturer guidelines. Ignoring these steps can cause premature wear and damage. It’s also a mistake to think break-in is just about engine speed or a one-time process. Keep these points in mind, and you’ll discover how to maximize your generator’s lifespan and reliability.

Key Takeaways

- Modern generators often do not require traditional break-in routines; follow manufacturer guidelines instead.

- Gradually increasing load and varying engine speed during initial operation is essential for proper piston ring seating.

- Skipping warm-up, coolant checks, or using improper oil can cause immediate and long-term engine damage.

- Regular inspections and documentation during break-in help detect early issues and prolong engine lifespan.

- Extended testing and avoiding heavy use before proper break-in can lead to premature wear and reduced reliability.

Assuming Break-In Is Unnecessary for New Generators

Many experts now believe that breaking in a new generator isn’t necessary if it’s properly manufactured and assembled. This challenges the common break in misconceptions that many people hold. You might have been told to run your generator at partial loads for hours, but recent insights suggest that these unnecessary procedures aren’t needed for modern units. Manufacturers design generators to meet strict quality standards, making traditional break-in routines redundant. Instead, focusing on proper operation from the start is more effective. The idea of a prolonged break-in period has become outdated, saving you time and effort. Trust that if your generator is from a reputable manufacturer, it’s ready to use without special procedures. Proper engine manufacturing standards ensure that your generator is built for immediate reliable performance, further supporting the notion that a break-in isn’t required. This shift helps you avoid unnecessary procedures and get your generator up and running swiftly.

Using Full Load Immediately After Installation

Applying full load immediately after installation can seem efficient, but it carries significant risks of overloading the generator. To prevent damage, you need to follow proper load testing steps and increase power gradually. Understanding these points helps ensure your generator operates safely and reliably from the start. Additionally, consulting best practices for generator maintenance can provide valuable guidance on load management.

Risks of Overloading Early

Jumping straight into full load operation right after installation can cause serious damage to your generator. Overloading early stresses components not yet broken in, risking reduced fuel efficiency and increased ambient noise. This can lead to overheating and premature wear, undermining your generator’s lifespan. Proper break-in prevents these issues by gradually increasing load. Here’s a quick comparison:

| Load Level | Effect on Fuel Efficiency | Ambient Noise Impact |

|---|---|---|

| Full Load Immediately | Poor, inefficient | High, disruptive |

| Gradual Loading | Improved, stable | Lower, manageable |

| No Load or Light Load | Ideal, gentle | Minimal |

| Moderate Load | Balanced, safe | Acceptable |

| Full Load (after break-in) | Peak efficiency | Manageable |

Taking time to break in your generator ensures longevity, efficiency, and quieter operation over time. Proper break-in procedures are essential to avoid early damage and ensure optimal performance.

Proper Load Testing Steps

While it might seem efficient to perform full load testing immediately after installation, doing so without proper preparation can be risky. To guarantee safety and peak performance, follow these steps:

- Check fuel efficiency by monitoring fuel consumption and engine response under full load, ensuring everything runs smoothly.

- Confirm noise reduction by listening for abnormal sounds, which could indicate issues needing attention before steady operation.

- Ensure proper cooling to prevent overheating, especially when running at full capacity for the first time, and verify all safety features are functioning.

- Monitor vibration levels to detect any imbalance or mechanical issues early, contributing to generator longevity and reliable operation.

Taking these steps helps protect your generator, improves fuel efficiency, and minimizes noise during operation, setting the stage for reliable, long-term use.

Gradual Power Increase

After completing initial load testing and verifying that your generator operates smoothly at full capacity, you might be tempted to run it at full load right away. However, rushing into full-power operation can hinder effective generator maintenance and compromise power stabilization. To guarantee peak performance, gradually increase the load over several hours or days, allowing internal components to settle and lubricate properly. This slow power increase helps prevent undue stress on the generator’s parts and reduces the risk of early wear or damage. Consistent, incremental loading also improves power stabilization, ensuring the generator runs reliably under full load later. Remember, patience during this process is key to long-term generator health and dependable operation. Understanding load management is essential for optimizing generator lifespan and functionality.

Ignoring the Manufacturer’s Break-In Guidelines

Ignoring the manufacturer’s break-in guidelines can lead to serious engine problems and reduce your generator’s lifespan. If you skip their advice, you risk issues like poor oil quality, increased engine noise, and premature wear. Here’s what can happen:

Skipping manufacturer break-in guidelines risks engine damage and shortens generator lifespan.

- You might use the wrong oil, which doesn’t provide proper lubrication during break-in, causing increased friction.

- Engine noise could be higher if break-in procedures aren’t followed, signaling improper seating of components.

- Premature engine wear occurs when parts aren’t properly bedded in, leading to costly repairs down the line.

Following the manufacturer’s instructions guarantees your generator runs smoothly, quietly, and lasts longer. Adhering to their guidelines helps protect your investment and keeps your generator reliable when you need it most.

Neglecting Proper Engine Warm-Up Before Operation

Skipping the proper engine warm-up before operating your generator can lead to immediate issues and long-term damage. Cold starts stress engine components, reducing fuel efficiency and causing unnecessary wear. A proper warm-up guarantees oil circulates fully, easing startup strain and improving noise reduction. When you neglect this step, you risk uneven engine performance and increased fuel consumption. Additionally, neglecting warm-up procedures can hinder your ability to maintain generator reliability over time.

Overlooking the Importance of Varying Load During Break-In

Ignoring the importance of varying load during break-in can lead to incomplete engine conditioning. By simulating real-use conditions, you help the generator adapt smoothly to different demands. This prevents unnecessary stress and promotes reliable long-term operation. Incorporating performance optimization into your break-in process ensures the engine functions efficiently under various scenarios.

Simulate Real Use Conditions

While simulating real use conditions is essential during generator break-in, many operators overlook the importance of varying the load throughout the process. Consistent load can cause uneven wear and hinder ideal performance. To guarantee a proper break-in, you should:

- Gradually increase and decrease the load to mimic actual usage, promoting better fuel efficiency and ensuring the engine adjusts smoothly.

- Vary load levels to reduce noise, making operation more comfortable and less disruptive.

- Avoid running at a constant high load for extended periods, which can cause unnecessary stress and reduce the generator’s lifespan.

- Incorporate AI-powered data analytics to monitor load patterns and optimize the break-in process for better long-term performance.

Prevent Equipment Stress

Varying the load during generator break-in is essential to prevent undue stress on the equipment. Keeping a consistent load can cause uneven wear and thermal stress, risking long-term damage. To guarantee proper load variation, consider your generator placement; a well-ventilated, stable location helps maintain consistent operation. Avoid running on poor fuel quality, as contaminated or low-grade fuel can cause fluctuations in engine performance, increasing stress. By gradually changing the load, you allow internal components to adapt smoothly, reducing the risk of overheating or mechanical failure. Proper fuel management and strategic generator placement optimize the break-in process, ensuring your generator performs reliably over its lifespan. Remember, a thoughtful load variation is key to preventing equipment stress during this critical phase. Additionally, monitoring sound recording techniques can help identify irregularities in operation that may indicate stress or malfunction, further safeguarding your investment.

Skipping Regular Inspection During the Break-In Period

Skipping regular inspections during the break-in period might seem like a time-saver, but it can lead to overlooked issues that could compromise engine performance and longevity. Without consistent checks, you might miss early signs of wear or damage. To keep your generator running smoothly, focus on these key areas:

- Scheduled maintenance: Follow the recommended inspection intervals to catch problems early.

- Fuel quality: Use fresh, clean fuel to prevent deposits and ensure proper combustion.

- Component checks: Regularly examine oil levels, filters, and connections for signs of wear or leaks.

- Understanding Somatic Therapy: Recognizing the importance of body awareness during maintenance can help identify physical signs of mechanical stress or fatigue in the generator.

Ignoring these inspections can result in reduced efficiency and costly repairs later. Staying vigilant during the break-in period ensures your generator performs reliably and lasts longer.

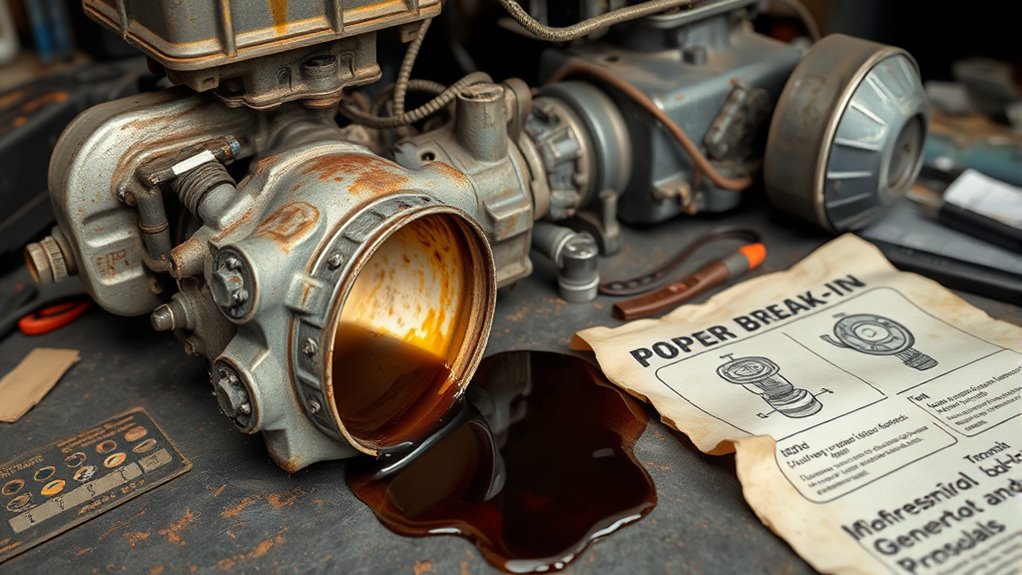

Using Low-Quality or Incompatible Oil for Break-In

Using low-quality or incompatible oil during the break-in process can cause serious engine problems. Oil quality directly affects how well your generator’s engine components wear in and form proper seals. Cheap or poor-grade oils often lack the necessary additives, leading to increased friction, heat, and wear during this critical period. Incompatible lubricants, such as using oil not rated for your engine type, can cause improper lubrication, corrosion, or sludge buildup. These issues compromise engine longevity and efficiency. Always choose high-quality, manufacturer-recommended oil to ensure proper break-in conditions. Avoid shortcuts by using subpar oils or mixing incompatible lubricants, as they hinder proper sealing and wear-in, potentially leading to costly repairs or reduced generator lifespan. Proper oil selection is essential for a successful break-in.

Relying on Short-Term Testing Instead of Extended Break-In

Relying solely on short-term testing can leave you unaware of hidden mechanical issues that only reveal themselves over time. While quick tests may seem efficient, they often don’t catch problems that affect long-term performance. Skipping extended break-in periods increases the risk of incomplete testing and potential generator failure later on.

Risks of Incomplete Testing

Short-term testing may seem sufficient initially, but it often overlooks critical issues that only emerge after extended operation. Rushing the break-in process can lead to problems with fuel efficiency and noise reduction down the line. Here are the risks:

- Increased wear and tear on engine components, causing long-term reliability issues.

- Poor fuel efficiency as parts haven’t properly seated or lubricated.

- Excessive noise due to unresolved vibrations or loose fittings.

Skipping extended testing may save time upfront but can result in costly repairs later. Without thorough break-in, you risk diminished performance and compromised safety. Extended testing ensures moving parts settle properly, maximizing fuel efficiency and noise reduction. Don’t underestimate the importance of complete testing—shortcuts today can lead to bigger problems tomorrow.

Short Runs vs. Long-Term Performance

While quick tests might seem to get the generator up and running faster, they often fail to reveal issues that only appear after extended operation. Short runs can improve initial startup times but don’t allow the generator to reach ideal fuel efficiency or noise reduction levels. During longer break-in periods, components settle, leading to better combustion and smoother operation. This results in improved fuel efficiency over time, saving you money and reducing emissions. Additionally, extended operation helps identify and minimize noise levels as parts wear in and settle into place. Relying solely on short-term testing might mask problems that only show up after hours of use, ultimately compromising long-term performance and durability. Proper long-term testing ensures your generator performs reliably, efficiently, and quietly when you need it most.

Hidden Mechanical Issues

Many mechanical issues can remain hidden if you only perform brief tests during the initial startup. Short-term testing often overlooks problems like inconsistent lubrication, which can cause long-term wear. It also risks missing engine calibration issues that only reveal themselves after extended use. To catch these hidden problems, focus on:

- Monitoring lubrication consistency over time to ensure smooth operation.

- Conducting longer runs to identify subtle engine calibration discrepancies.

- Observing how components settle after initial startup, revealing wear or misalignments.

Skipping extended break-in can lead to overlooked issues that worsen with use, ultimately shortening your generator’s lifespan. Relying solely on short-term tests leaves potential problems unaddressed, so invest in thorough, prolonged testing to ensure your generator runs reliably and efficiently.

Failing to Document Break-In Procedures and Results

Failing to document break-in procedures and results can lead to significant operational issues. Without proper documentation, you risk falling into common documentation pitfalls that compromise your ability to troubleshoot and optimize the generator’s performance later. Record keeping importance becomes clear when you need to track how the generator behaves during break-in, noting any anomalies or adjustments made. Skipping these steps may cause you to overlook early signs of mechanical problems or improper lubrication, which could lead to costly repairs. Additionally, incomplete records hinder future maintenance planning and warranty claims. To avoid these pitfalls, ensure every step and observation is thoroughly documented. Clear, accurate records empower you with crucial information needed for long-term reliability and efficient operation of your generator.

Overlooking Cooling System Checks During Break-In

Ignoring cooling system checks during break-in can lead to overheating and engine damage. You should regularly check coolant levels, inspect the radiator for proper function, and monitor temperature gauges closely. These steps help guarantee your generator runs smoothly and avoids costly issues.

Check Coolant Levels

You should always verify the coolant levels before and during the break-in period to guarantee the engine stays properly cooled. A thorough coolant check prevents overheating and ensures peak performance. Start by inspecting the coolant reservoir and radiator for proper fluid levels. Next, look for any leaks or signs of corrosion during your radiator inspection. Finally, top off the coolant if levels are low, using the recommended type. This simple step helps maintain consistent engine temperature and avoids damage during break-in. Remember, neglecting this check can lead to overheating, which compromises engine longevity. Regularly monitoring coolant levels keeps your generator running smoothly and minimizes downtime caused by cooling system issues. Stay vigilant, and your generator will thank you for it.

Inspect Radiator Functionality

After verifying coolant levels, it’s important to guarantee the radiator is functioning properly. Check for any coolant leaks around fittings, hoses, and the radiator itself, as leaks can cause overheating or damage. Inspect the radiator for dirt, debris, or buildup that could hinder airflow, and perform radiator cleaning if needed. A clean radiator ensures efficient heat dissipation, preventing overheating during break-in. Look for signs of corrosion or damage that might impair cooling capacity. If you notice any leaks or blockages, address them immediately before proceeding. Proper radiator inspection helps maintain ideal engine temperature and prevents issues that could compromise the generator’s performance during this critical phase. Skipping this step risks overheating and potential engine failure.

Monitor Temperature Gauges

Have you been monitoring the temperature gauges regularly during generator break-in? Keeping an eye on these gauges is essential for proper coolant maintenance and preventing overheating. Here’s what you should do:

- Watch for temperature spikes that could indicate coolant system issues or the need for spark plug replacement.

- Make sure the cooling system maintains a steady temperature, avoiding fluctuations that signal airflow or coolant flow problems.

- Record temperature readings to track any trends, so you can address potential problems early.

Believing Break-In Only Matters for Large or Industrial Units

Many people believe that break-in procedures only matter for large or industrial generators, but this isn’t the case. Even smaller units benefit from proper break-in, as factory testing and manufacturer guidelines emphasize. These initial runs help ensure the engine’s moving parts seat correctly, reducing wear and potential damage down the line. Skipping this step or rushing through it can lead to reduced efficiency and shorter lifespan, regardless of the generator’s size. Following manufacturer instructions during break-in helps you build a reliable, long-lasting unit. Properly breaking in your generator isn’t just for big commercial setups; it’s essential for any new or serviced unit to perform at its best and avoid costly repairs later.

Ignoring Break-In for Portable Generators or Small Units

Ignoring the break-in process for portable generators or small units can seem harmless, but it often leads to avoidable issues. Skipping this step can disrupt proper engine wear and reduce long-term reliability. Without a proper break-in, your generator’s maintenance schedules might become more frequent, and fuel efficiency can suffer. To avoid these problems, keep these tips in mind:

- Follow manufacturer guidelines during the initial run to ensure ideal engine performance.

- Vary engine load levels gradually to promote even wear and prevent premature damage.

- Regularly check and change oil as part of your maintenance schedule to maintain fuel efficiency and prolong lifespan.

Neglecting these steps can cost you more in repairs and fuel costs down the line. Proper break-in sets the foundation for reliable, efficient operation.

Thinking Break-In Is Just About Engine Speed; Ignoring Other Factors

While engine speed is often emphasized during break-in, it’s a mistake to think that’s the only factor to contemplate. Proper break-in involves more than just keeping the engine at specific speeds; load management plays a vital role. You need to vary the load to guarantee the engine experiences different operating conditions, which helps seat the piston rings and lubricate components effectively. Running the generator at a constant speed or load can cause uneven wear and incomplete break-in. Instead, gradually increase and decrease the load while maintaining appropriate engine speed. This approach promotes better sealing, reduces stress, and guarantees all parts adapt properly. Remember, a thorough break-in considers both engine speed and load management for peak performance and longevity.

Failing to Allow Proper Break-In Time Before Heavy Use

Jumping into heavy use too soon after starting your generator can cause premature wear and damage. Skipping proper break-in time affects engine longevity and fuel efficiency. To avoid this, focus on these key steps:

- Run the generator at low loads for the first few hours to let internal parts settle smoothly.

- Vary the load periodically, preventing constant strain on the engine.

- Follow manufacturer guidelines for break-in duration, typically around 20-30 hours.

Assuming Break-In Is a One-Time Task and Not an Ongoing Process

Many assume that once the initial break-in period is complete, no further special care is needed. In reality, break-in is an ongoing process that requires regular attention. Failing to follow maintenance scheduling can lead to operator fatigue, overlooked issues, and eventual equipment failure. Continuous monitoring ensures the engine stays properly lubricated and avoids premature wear.

| Break-In Step | Ongoing Maintenance |

|---|---|

| Use light loads initially | Regular oil changes |

| Avoid high RPMs early | Periodic inspections |

| Check for unusual noises | Operator fatigue management |

| Follow manufacturer guidelines | Scheduled testing and servicing |

| Record performance data | Staying alert to early signs |

Frequently Asked Questions

How Often Should Break-In Procedures Be Reviewed After Initial Setup?

You should review your generator’s break-in procedures regularly, ideally during scheduled maintenance and operator training sessions. Typically, reviewing every 3 to 6 months ensures your team stays updated on best practices and any manufacturer recommendations. Consistent reviews help prevent issues, extend equipment lifespan, and maintain peak performance. Keep detailed records of these reviews to track improvements and ensure everyone follows correct procedures, making your generator dependable when you need it most.

Can Environmental Conditions Affect the Generator’s Break-In Process?

Environmental conditions can greatly impact your generator’s break-in process, like a storm shaping a river’s course. Extreme temperatures, humidity, or dust can hinder lubrication and cause wear. These environmental factors influence your generator’s durability, so you need to adapt your break-in procedures accordingly. By controlling or monitoring these conditions, you help guarantee your generator runs smoothly and lasts longer, safeguarding your investment against unnecessary damage.

What Are the Signs Indicating the Need for a Break-In Extension?

You should consider extending the break-in if you notice unusual generator noise or increased oil consumption. These signs suggest the internal components aren’t fully settled, and continuing the break-in helps prevent long-term damage. Keep monitoring your generator closely, and if these issues persist or worsen, an extension guarantees proper seating of parts and peak performance. Always follow manufacturer guidelines, and don’t rush the process.

Is There a Recommended Break-In Protocol for Dual-Fuel Generators?

You should follow a specific break-in protocol for dual-fuel generators to ensure longevity and performance. Use high-quality fuel and select the right oil to reduce wear and tear. Run the generator at varying loads, monitor fuel quality, and change the oil regularly. Keep an eye on temperature and pressure gauges, and follow manufacturer recommendations. Properly establishing your generator guarantees reliable operation, efficiency, and extended lifespan.

How Does Break-In Impact Long-Term Generator Reliability and Maintenance?

Breaking in your generator is vital for long-term reliability and maintenance. Proper break-in procedures enhance its longevity by ensuring parts wear evenly and function smoothly. By following recommended break-in protocols, you reduce future maintenance needs and prevent early failures. This initial care helps sustain peak performance, making maintenance schedules more manageable and cost-effective over time. Ultimately, a well-executed break-in supports your generator’s durability and dependable operation for years to come.

Conclusion

Don’t overlook the importance of proper break-in procedures. For example, skipping the warm-up phase could cause engine damage, just like it did for a small business owner who faced costly repairs. By following manufacturer guidelines and varying load gradually, you guarantee your generator runs smoothly and lasts longer. Remember, break-in isn’t a one-time event—it’s an ongoing process that protects your investment and keeps power flowing when you need it most.