If you suspect fuel contamination, look for signs like engine hesitation, misfires, or reduced performance, along with visual clues such as cloudy fuel, sediment, or tank residue. Check for water in the tank by noting layers or sediment, and test with water separation kits. Proper storage, regular inspections, and quality testing can prevent issues. Keep your equipment running smoothly—continue exploring these tips to learn how to identify and fix fuel problems effectively.

Key Takeaways

- Recognize signs like engine misfires, stalling, and poor performance to identify potential fuel contamination early.

- Conduct visual inspections for cloudy fuel, sediment, or discoloration in tanks and filters.

- Detect water in fuel by checking for sediment layers or using water separation additives and kits.

- Follow best storage practices: regular inspection, proper sealing, and rotating fuel to prevent degradation.

- Use compatible fuel stabilizers and additives, and maintain routine tank cleaning to preserve fuel quality.

Recognizing Signs of Fuel Contamination in Your Equipment

Fuel contamination can quickly cause equipment problems, so recognizing the signs early is vital. One key indicator is poor engine performance, which may include stalling, misfires, or difficulty starting. Dirty or degraded fuel often results from improper fuel storage, allowing water or debris to enter your tank. Be aware that fuel additives can help prevent contamination by stabilizing fuel and reducing buildup, especially if your equipment sits unused for long periods. If you notice unusual odors or the presence of sediment in your fuel, it’s a sign you need to check for contaminants. Regularly inspecting your fuel and maintaining proper storage conditions can help prevent issues. Proper fuel storage is essential to avoid contamination and keep your equipment running smoothly. Catching these signs early keeps your equipment running smoothly and minimizes costly repairs.

Common Visual Clues Indicating Contaminated Fuel

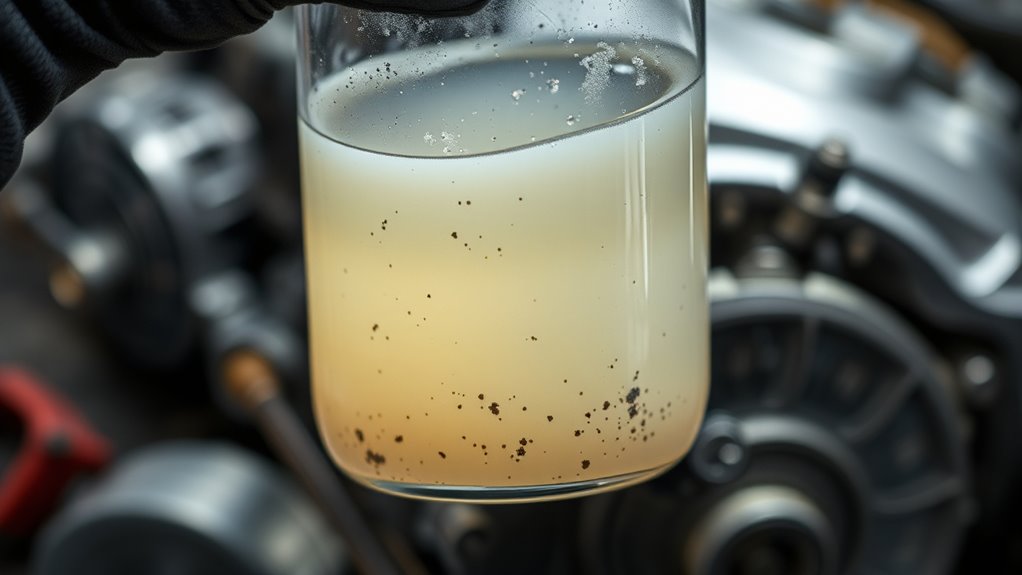

When inspecting your equipment, visual clues can quickly reveal contaminated fuel. One key sign is fuel filter discoloration; if the filter appears cloudy, dark, or murky, contamination is likely. Next, check the fuel tank residue—if you notice sludge, sediment, or a thick film lining the tank, contaminants are present. Also, look for fuel that appears cloudy or has an unusual color, such as brown or black, instead of clear. Finally, signs like sediment buildup around the fuel inlet or visible particles in the fuel indicate contamination. These visual cues help you identify issues early, preventing further damage. Regularly inspecting these indicators can save time and costly repairs, ensuring your equipment runs smoothly. Additionally, understanding the industrial juice manufacturing process can help you recognize signs of contamination during fuel handling and storage.

How to Detect Water Presence in Fuel Tanks

Detecting water in your fuel tank is essential to prevent engine issues and costly repairs. One effective method involves using fuel additives designed for water separation. These additives help break down water droplets, making them easier to identify and remove. After adding the additive, run the engine briefly, then check the fuel filter or drain plug for any water collection. Another tip is to observe the fuel’s appearance; water often settles at the bottom of the tank or in the filter, creating a layer or causing sediment. Regularly inspecting and testing your fuel with water separation products ensures you catch water contamination early. Using appropriate testing kits can also help confirm the presence of water in your fuel. By staying proactive, you can avoid fuel-related problems and keep your engine running smoothly.

Symptoms of Engine Performance Issues Due to Fuel Quality

If your engine starts hesitating or stalls unexpectedly, poor fuel quality could be to blame. You might also notice a drop in fuel efficiency or strange noises coming from the engine. Recognizing these signs early helps prevent more serious damage and keeps your vehicle running smoothly. Additionally, contaminated fuel can lead to engine damage, emphasizing the importance of quality fuel and proper maintenance.

Engine Hesitation and Stalling

Engine hesitation and stalling often signal trouble with fuel quality, especially when contaminants or water have entered the system. When this happens, your engine struggles to run smoothly, causing sudden stalls or uneven acceleration. To prevent this, consider using fuel additives designed to clean fuel injectors and remove water from the system. Proper fuel storage is vital; stale or contaminated fuel can lead to ongoing issues. Here are key points to address this problem:

- Regularly add fuel additives to keep fuel clean and water-free.

- Store fuel in sealed, approved containers to prevent contamination.

- Use fuel stabilizers if storing fuel for extended periods.

- Monitor fuel quality before filling up to avoid contaminated supplies.

- Understanding the role of fuel quality in engine performance helps prevent hesitation and stalls.

Addressing these factors helps maintain engine performance and avoids hesitation caused by poor fuel quality.

Reduced Fuel Efficiency

Reduced fuel efficiency is often a sign that your engine isn’t getting the quality fuel it needs to perform ideally. Contaminated fuel, especially from poor fuel storage, can lead to incomplete combustion and lower mileage. When fuel sits too long or isn’t stored properly, it can develop water or microbial growth, which hampers engine performance. Using fuel additives can help clean your fuel system and improve efficiency, but if the fuel quality is compromised, additives alone won’t fully solve the problem. Consistently poor mileage may indicate contaminated fuel or degraded fuel quality. To prevent this, always buy from reputable sources and consider treating stored fuel with stabilizers or additives when storing for extended periods. Proper fuel handling is key to maintaining optimal fuel efficiency. Additionally, modern fuel filters and air purifier features can help remove contaminants before they reach the engine, further protecting your vehicle’s performance.

Unusual Engine Noises

Unusual engine noises can be a clear sign that fuel quality issues are affecting your vehicle’s performance. If you hear knocking, sputtering, or whining sounds, it may indicate contaminated fuel or poor fuel additive effects. These noises often occur when the engine struggles to combust contaminated fuel properly. To prevent this, follow proper fuel storage tips, such as keeping your tank filled to avoid moisture buildup. Additionally, using high-quality fuel additives can help neutralize contaminants and improve combustion. Be attentive to persistent noises, as they suggest your fuel might contain water or debris. Regular maintenance and fuel quality checks are essential to avoid engine damage caused by poor fuel. Addressing these symptoms promptly can save you costly repairs later. Monitoring engine performance regularly can help identify early signs of fuel contamination before significant damage occurs.

Troubleshooting No-Start Conditions Caused by Fuel Problems

When your vehicle won’t start, fuel issues are often to blame, and pinpointing the problem quickly can save you time and money. Begin with a fuel tank inspection to check for water, debris, or contamination. If you notice sediment or a strange smell, your fuel might be compromised. Using a fuel additive can help stabilize the fuel and improve its combustion qualities, especially if your fuel is old or degraded. Make certain the fuel is flowing properly by checking the fuel pump and filter. Sometimes, clogged filters or a failing pump cause no-start conditions. Eliminating these issues can often be achieved with routine inspections and the right fuel additive use, restoring proper fuel flow and engine start-up. Additionally, understanding industry transformations like AI automation can help you stay informed about emerging solutions for vehicle diagnostics and repair.

Preventative Measures to Avoid Fuel Contamination

Preventing fuel contamination starts with proactive maintenance and good fueling habits. To keep fuel clean and reliable, focus on storage best practices and proper fuel additive formulations. Regularly inspect storage tanks for signs of water or sediment buildup. Rotate fuel supplies, ensuring older fuel is used first, reducing the risk of degradation. Additionally, implementing storage organization solutions can help prevent cross-contamination and maintain fuel quality over time.

Frequently Asked Questions

Can Contaminated Fuel Cause Long-Term Engine Damage?

Yes, contaminated fuel can cause long-term engine damage. If you don’t use fuel stabilizers or properly treat fuel stored in tanks, contaminants like water or dirt can accumulate and corrode engine parts over time. Regularly inspecting and cleaning your storage tanks helps prevent this. Ignoring contaminated fuel can lead to clogging, corrosion, and expensive repairs, so always guarantee your fuel is clean and stabilized to protect your engine’s longevity.

How Often Should Fuel Samples Be Tested for Contamination?

You should test your fuel regularly, ideally every three to six months, depending on usage and storage conditions. This guarantees timely contamination detection using effective methods like visual inspection, fuel test kits, and laboratory analysis. Regular fuel testing frequency helps catch contaminants early, preventing engine damage and costly repairs. If your equipment sits unused for long periods, increase testing frequency to maintain fuel quality and guarantee peak engine performance.

Are There Specific Fuel Additives That Prevent Contamination?

Ever wonder if specific fuel additives can prevent contamination? Yes, fuel stabilizers are designed for this purpose, enhancing additive effectiveness and keeping your fuel clean. Look for stabilizers with antioxidants and anti-foaming agents, which help prevent microbial growth and water accumulation. Always choose reputable brands, follow the recommended dosage, and store fuel properly. This way, you guarantee your fuel remains contamination-free and your engine runs smoothly.

What Are the Safety Procedures for Handling Contaminated Fuel?

When handling contaminated fuel, you should wear safety gear like gloves and goggles to protect yourself. First, stop using the fuel and isolate the contaminated batch. Use proper fuel filtration methods to remove contaminants, and never pour it down drains. Ventilate the area well and avoid sparks or flames. Always follow your company’s safety procedures and dispose of contaminated fuel responsibly at designated disposal sites.

How Does Temperature Affect Fuel Contamination Risks?

Temperature markedly impacts fuel contamination risk because higher fuel temperatures can promote microbial growth and accelerate chemical reactions that lead to contamination. When fuel temperature rises, bacteria and fungi thrive, increasing contamination chances. Conversely, colder temperatures slow microbial activity, reducing risk. You should monitor fuel temperature regularly, especially during storage and transfer, to prevent contamination. Keeping fuel within recommended temperature ranges helps maintain fuel quality and minimizes contamination risks effectively.

Conclusion

Regularly checking your fuel for contamination can save you time and costly repairs. Did you know that over 30% of engine failures are linked to poor fuel quality? By staying alert to visual clues, water presence, and performance issues, you can catch problems early. Implement preventive measures to keep your equipment running smoothly and avoid unexpected breakdowns. Staying proactive with fuel maintenance isn’t just smart — it’s essential for reliable operation.