To keep your food truck’s power system reliable and safe, regularly inspect and maintain your engine, batteries, generator, and electrical wiring. Manage load distribution carefully, use surge protectors, and keep backup systems like solar or portable generators ready for outages. Staying organized and clean guarantees quick troubleshooting and longevity. If you follow these key tips, you’ll ensure smooth operation and can handle any power issues with confidence—continue to explore for detailed steps and best practices.

Key Takeaways

- Conduct regular inspections of engine, electrical systems, and weather-related components to prevent failures and prolong truck lifespan.

- Maintain and monitor batteries, solar panels, and charging procedures to ensure reliable power and extend component longevity.

- Perform routine generator maintenance, including oil checks and troubleshooting common issues for continuous operation.

- Follow safety protocols during electrical system checks, using insulated tools and inspecting wiring for damage.

- Manage power distribution effectively, implement backup systems like solar and generators, and maintain organized components for quick troubleshooting.

Regular Inspection and Preventive Maintenance Routines

Regular inspections and preventive maintenance are essential for keeping your food truck running smoothly and avoiding costly breakdowns. By routinely checking your engine, electrical systems, and fuel lines, you ensure peak fuel efficiency and prevent unexpected failures. Pay close attention to weather preparedness; extreme temperatures or humidity can impact your vehicle’s performance. Regularly inspecting tires, seals, and vents helps protect against weather-related damage and keeps your truck operating reliably. Staying proactive with maintenance also means catching issues early, reducing repair costs and downtime. Keep detailed logs of inspections and repairs to track patterns and plan future upkeep. Additionally, understanding the importance of vetted maintenance practices can significantly improve your truck’s longevity and performance. Ultimately, consistent routines improve your truck’s dependability, save money, and ensure you’re always ready to serve your customers without interruption.

Battery Care and Management Strategies

Keeping your batteries in good shape starts with sticking to a regular inspection schedule to catch any issues early. Using proper charging techniques guarantees your batteries stay healthy and perform reliably during busy hours. Additionally, implementing protective styling benefits can help reduce strain on your batteries by minimizing unnecessary usage. By managing these strategies, you’ll extend your battery life and keep your food truck running smoothly.

Battery Inspection Schedule

To guarantee your food truck’s battery stays in peak condition, establishing a consistent inspection schedule is essential. Regular checks help identify issues early, preventing unexpected breakdowns. During inspections, examine your batteries for corrosion, leaks, or swelling, and ensure terminal connections remain tight. If your truck uses solar panels, verify they’re clean and functioning efficiently, as they contribute to battery longevity. Also, monitor inverter maintenance, since a well-maintained inverter helps optimize power flow and reduces strain on your batteries. Schedule inspections at least once every three months, or more frequently if you heavily rely on solar energy or experience extreme weather. Incorporating preventive maintenance into your routine can further extend your battery lifespan and improve overall performance. Consistent inspections will keep your battery system reliable, extend its lifespan, and ensure your food truck stays powered up when you need it most.

Proper Charging Techniques

Proper charging techniques are essential for maintaining your food truck’s battery health and ensuring reliable power during your busy shifts. To optimize battery life, always use the correct charger specified for your battery type. Avoid overcharging by disconnecting the charger once the battery reaches full capacity, as this prevents damage and extends lifespan. Regularly monitor voltage levels and temperature during charging to prevent overheating or undercharging. Protect your battery from extreme temperatures and keep it in a well-ventilated area. Consistent charging practices promote battery optimization, reducing the risk of unexpected failures. Proper battery maintenance not only prolongs battery life but also ensures your food truck remains powered and ready to serve customers efficiently. Implementing proper charging techniques now saves you time and money later.

Generator Maintenance and Troubleshooting Tips

To keep your generator running smoothly, you need to regularly check the oil levels and change the oil when needed. If your generator isn’t starting or running properly, troubleshooting common issues like fuel problems or electrical faults can save you time. Knowing these maintenance and troubleshooting tips helps make certain your food truck stays powered up during busy hours. Additionally, ensuring your generator’s components are well-maintained can prevent potential issues with power supply stability.

Generator Oil Checks

Ever wondered why regular oil checks are crucial for your generator’s performance? Keeping the oil at the right level and quality ensures your generator runs smoothly, improving fuel efficiency and reducing unnecessary fuel consumption. Regular checks help prevent engine wear caused by dirt and debris, which can lead to costly repairs and downtime. When you inspect the oil, look for a clean, amber color and avoid dark, thick, or gritty texture. Using the correct type of oil recommended by the manufacturer maximizes performance and minimizes noise during operation. Consistent oil checks also help you catch leaks early, preventing potential damage. Proper oil quality and level are essential for maintaining optimal engine performance, and regular maintenance extends the lifespan of your generator. Remember, well-maintained oil keeps your generator running quietly and efficiently, so make it a routine part of your maintenance schedule.

Troubleshooting Common Issues

When your generator isn’t running smoothly, identifying and fixing common issues quickly can save you time and money. Start by checking the fuel supply—poor fuel quality or low levels can reduce fuel efficiency and cause inconsistency. Clean or replace the air filter, as a dirty filter hampers performance. Overloading the generator affects both power output and fuel efficiency, so review your menu planning to avoid exceeding capacity. Regularly inspect spark plugs and wiring for wear or damage. If the generator stalls or runs unevenly, it might need a tune-up. Keeping these issues in check helps maintain ideal fuel efficiency, ensuring your food truck runs reliably. Proper troubleshooting keeps your power system in top shape, supporting smooth service and efficient menu operation. Additionally, understanding effectiveness of maintenance can help you optimize your generator’s performance over time.

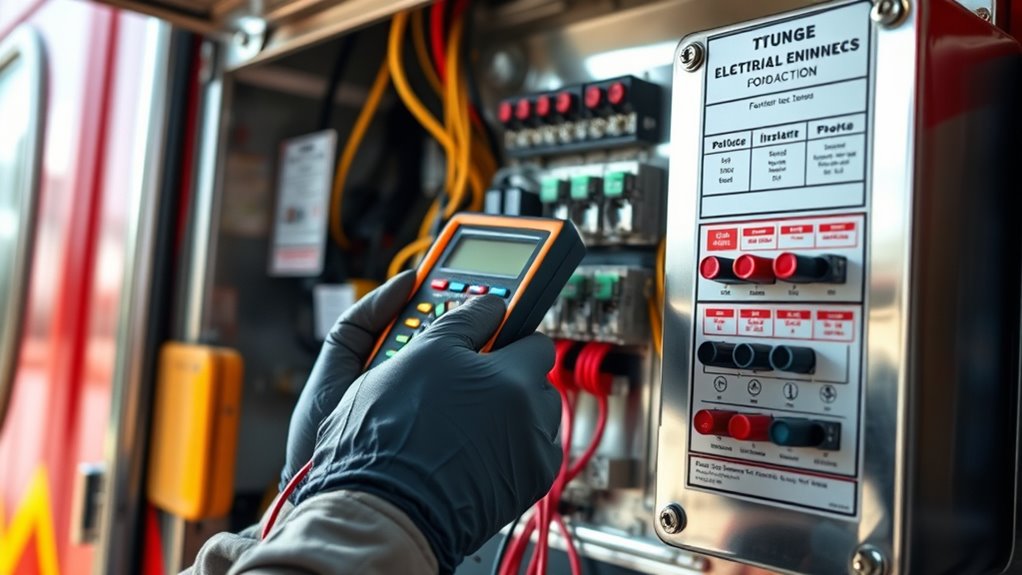

Electrical System Checks and Safe Handling Practices

Before performing any maintenance or inspections on your food truck’s electrical system, you should always verify the power is completely shut off. This ensures circuit safety and prevents accidental shocks. When inspecting electrical wiring, handle components carefully and avoid shortcuts that compromise safety. Here are essential steps:

- Confirm the main disconnect switch is off before touching any wiring.

- Use insulated tools to minimize risk during checks.

- Visually inspect wiring for wear, corrosion, or damage, and replace if needed. Regularly check for signs of wear or damage to maintain electrical safety and system integrity.

Following these practices helps prevent electrical hazards and maintains a safe environment. Always remember, working with electrical systems requires respect for potential dangers. Proper handling not only protects you but also ensures your truck’s electrical system stays reliable and efficient.

Power Distribution and Load Management

Effective power distribution is essential for ensuring your food truck operates smoothly and safely. Proper load management prevents circuit overloads, which can trip breakers or damage equipment. To avoid this, distribute appliances across multiple circuits, keeping high-wattage devices separate. Monitor your power usage regularly to prevent exceeding your system’s capacity. Power surges can occur from sudden electrical spikes, risking damage to sensitive equipment. Using surge protectors helps guard against these surges. Always plan your power distribution setup carefully, considering each device’s wattage and the truck’s total load. Keep an eye on circuit breakers and reset them if they trip. Good load management minimizes the risk of electrical issues, ensures stable power flow, and keeps your operations running smoothly without unexpected interruptions. Additionally, understanding the effectiveness of hydrocolloid patches can help you better protect your equipment from moisture-related damage.

Emergency Power Backup Protocols

Having a solid emergency power backup plan is essential to keep your food truck operational during power outages. It ensures you can serve customers without interruption. Focus on integrating solar power with your system for sustainable backup energy. When choosing an inverter, prioritize reliability and compatibility with your solar setup to handle peak loads. A well-designed protocol includes: 1. Installing a backup power source, like a portable generator or solar integration, to provide immediate power. 2. Selecting the right inverter to efficiently convert stored or alternative energy into usable power. 3. Establishing clear procedures for switching to backup power promptly, minimizing downtime and protecting sensitive equipment. Additionally, considering total‑cost clarity in your backup system can help you make informed decisions that balance initial investment and ongoing maintenance needs.

Keeping Your Power System Clean and Organized

Keeping your power system clean and organized is essential for reliable operation and quick troubleshooting. Regularly maintaining your power system organization ensures components are accessible and issues are easier to detect. Implementing consistent cleaning schedules prevents dust and debris buildup that can cause overheating or electrical faults. Use the table below to help structure your maintenance routine:

| Task | Frequency | Purpose |

|---|---|---|

| Inspect connections | Weekly | Prevent loose wiring |

| Clean terminals | Monthly | Avoid corrosion |

| Check vents | Bi-weekly | Maintain proper airflow |

Sticking to these schedules keeps your system efficient, reduces downtime, and extends component lifespan. Staying organized is key to a dependable power setup on your food truck.

Frequently Asked Questions

How Often Should I Replace the Main Power Inverter?

You should replace the main power inverter every 5 to 10 years, depending on usage and maintenance. Regular battery maintenance can prolong its inverter lifespan, but signs like overheating or frequent shutdowns mean it’s time for a replacement. Keep an eye on performance and consult your manufacturer’s guidelines. Proper maintenance ensures your inverter stays reliable longer, helping your food truck run smoothly without unexpected power issues.

What Are Signs of Failing Electrical Wiring in My Truck?

Think of your truck’s wiring like a nervous system—when it starts misfiring, trouble’s brewing. Signs of failing electrical wiring include flickering lights, frequent circuit breaker trips, or burning smells. You should perform circuit troubleshooting and consider wiring upgrades if issues persist. If you notice corrosion or frayed wires, get them checked immediately to prevent a breakdown. Staying proactive keeps your truck running smoothly and prevents costly repairs down the line.

How Can I Upgrade My Power System for Increased Load?

To upgrade your power system for increased load, consider a solar upgrade combined with expanding your battery capacity. Install higher wattage solar panels to generate more energy and add larger or additional batteries to store it efficiently. This approach guarantees a steady power supply, reduces reliance on generators, and supports your growing equipment needs. Regularly check your system’s compatibility and consult a professional to optimize the upgrade safely and effectively.

What Safety Precautions Are Essential During Electrical Repairs?

During electrical repairs, you should prioritize safety by wearing personal protective equipment like insulated gloves and safety goggles. Always disconnect the power before starting work to prevent electrical shock, and keep a fire extinguisher nearby in case of fire safety emergencies. Guarantee your work area is dry and well-ventilated, and avoid working alone. Following these precautions helps protect you from potential hazards and maintains a safe working environment.

How Do I Troubleshoot Intermittent Power Outages?

Imagine your power flickering like a faulty light bulb—your first step is to verify your generator maintenance. Inspect connections, fuel levels, and the generator’s condition. Then, move to battery troubleshooting: ensure batteries are charged, terminals are clean, and cables are secure. Intermittent outages often stem from these issues. Regularly maintaining your generator and batteries keeps your food truck running smoothly and prevents unexpected power disruptions.

Conclusion

Maintaining your food truck’s power system keeps it reliable and safe. Regular inspections prevent costly breakdowns, while proper care extends equipment lifespan. Neglect the clutter, and troubleshooting becomes chaos. Stay organized, and troubleshooting turns into a quick fix. Power is your truck’s heartbeat—keep it clean, managed, and ready. Because when your power’s in top shape, your food truck runs smoothly, and your business thrives. Stay vigilant, stay powered, and serve with confidence.