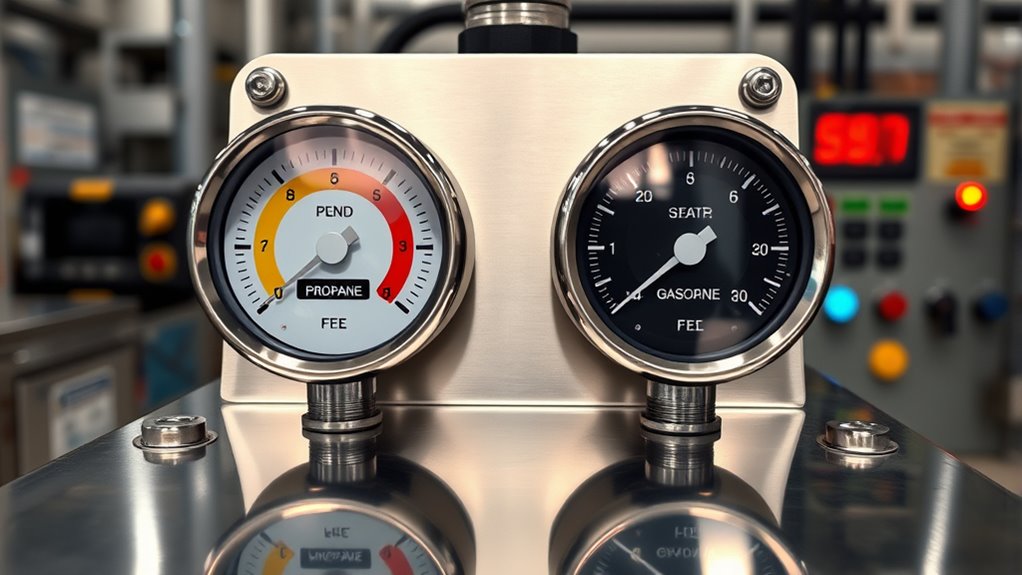

To accurately compare propane and gasoline runtime, consider their energy content, consumption rates, and engine efficiency, all guided by local and federal codes. Propane often lasts longer due to cleaner burning and lower fuel use, while gasoline provides quick bursts but needs frequent refueling. Ensuring compliance with safety standards and proper handling is essential for safe operation. Keep informed on regulations and best practices to make the right choice—more advice ahead will help you navigate this process confidently.

Key Takeaways

- Propane offers longer runtime per tank due to higher energy content and cleaner combustion, reducing refueling frequency.

- Gasoline provides quick, high-power bursts but consumes fuel faster, impacting overall efficiency and runtime.

- Compliance with emission standards and certification ensures engines operate legally and safely with proper fuel use.

- Proper storage, handling, and regular maintenance are essential to meet safety codes and maximize fuel efficiency.

- Understanding local and federal regulations helps ensure correct fueling practices and avoid legal penalties.

Understanding Fuel Runtime: Propane Vs Gasoline

While both propane and gasoline are commonly used fuels, they differ substantially in how long they can run a device or engine. Your choice of fuel type impacts runtime, with propane generally providing longer operation times per tank due to its higher energy content and lower consumption rate. When doing an efficiency comparison, propane often surpasses gasoline in fuel economy because it burns cleaner and more completely, reducing waste. Gasoline, on the other hand, tends to deliver quick bursts of power but requires more frequent refueling, especially in high-demand applications. Understanding this difference helps you plan better for your needs, whether for prolonged use or quick, intense power. Additionally, fuel storage safety is a critical aspect to consider when choosing between these fuels. Ultimately, your fuel type choice directly influences the duration your device or engine can operate without interruption.

Key Factors Influencing Fuel Efficiency and Performance

Several factors directly impact the efficiency and performance of propane and gasoline as fuel sources. One key factor is the type of alternative fuel you choose, as propane typically burns cleaner and can offer smoother operation. Engine design and maintenance also play a role, influencing how well each fuel combusts and delivers power. Additionally, adherence to emission standards affects performance; stricter standards often lead to optimized engines that maximize fuel efficiency while reducing pollutants. The fuel’s energy density impacts runtime, with gasoline generally providing more energy per volume, but propane’s cleaner burn can offset this in some cases. Moreover, fuel storage methods and proper handling can influence overall efficiency and safety. Ultimately, understanding these factors helps you select the right fuel for your needs, balancing efficiency, performance, and compliance.

Regulatory Standards for Propane and Gasoline Engines

Regulatory standards play a crucial role in shaping the design and operation of propane and gasoline engines. These standards guarantee engines meet specific emission standards, reducing harmful pollutants and protecting the environment. They also set guidelines for the use of fuel additives, which can improve performance and lower emissions. For propane engines, regulations often focus on clean-burning requirements and compatibility with fuel additives that enhance combustion. Gasoline engines are subject to strict emission standards, including limits on volatile organic compounds and nitrogen oxides. Compliance requires manufacturers to incorporate technologies like catalytic converters and fuel formulation controls. Staying up to date with these standards helps you avoid legal issues and ensures your engine operates efficiently, safely, and within the environmental boundaries set by authorities.

Safety Considerations and Handling Requirements

You need to follow proper storage practices to prevent leaks and fires when handling propane or gasoline. Always wear the right personal protective equipment to keep yourself safe from spills, fumes, or accidental ignition. Paying close attention to these safety measures helps you avoid accidents and guarantees safe operation. Additionally, understanding the flammability and safety guidelines is essential for minimizing risks associated with these fuels.

Proper Storage Practices

Proper storage of propane and gasoline is essential for safety and to prevent accidents. You must guarantee your fuel storage areas are secure, well-ventilated, and away from heat sources. Regular container maintenance is key—check for leaks, corrosion, and proper labeling. Use approved containers and never reuse damaged ones, as compromised containers can lead to dangerous spills or explosions. Keep fuels in a cool, dry place, and avoid storing them inside living spaces. Always keep fire extinguishers nearby and follow local codes for storage limits. To evoke a sense of responsibility, remember:

- Store fuels out of children’s reach

- Inspect containers regularly for damage

- Keep storage areas clean and dry

- Never mix different fuels in the same container

Additionally, practicing creative practice can foster a mindset of careful planning and safety awareness in handling hazardous materials.

Personal Protective Equipment

Handling propane and gasoline safely requires wearing the right personal protective equipment (PPE) to minimize the risk of accidents and injuries. Always wear fire resistant gear to protect against potential fires or explosions. Chemical resistant gloves are essential to prevent skin contact with hazardous fuels, reducing the risk of burns or absorption of toxic substances. Use safety goggles or a face shield to guard your eyes from splashes or vapors. Ensure your PPE fits properly and is in good condition before handling fuels. Remember, PPE not only shields you from immediate hazards but also helps you comply with safety standards and regulations. Regularly inspecting your gear and replacing any damaged items is crucial to maintain maximum protection during fuel handling and transfer. Proper PPE usage plays a vital role in ensuring safety and preventing accidents.

Compliance Requirements for Different Equipment and Vehicles

You need to understand the regulatory standards that apply to propane and gasoline equipment and vehicles. Certification processes guarantee your equipment meets safety and performance requirements. Regular compliance checks help keep your vehicles and tools legal and safe to operate. Security measures are increasingly integrated into various safety protocols to enhance overall compliance and protection.

Regulatory Standards Overview

Regulatory standards for propane and gasoline equipment are designed to guarantee safety, environmental protection, and operational efficiency. You must pay attention to fuel tank materials, making certain they meet strict durability and safety criteria. Emission standards aim to reduce pollutants, protecting air quality and public health. These standards regulate vehicle and equipment design, fueling systems, and maintenance practices. Implementing vertical storage solutions can also help optimize space and safety in storage areas. Be aware that these regulations can evoke strong feelings—safety, environmental responsibility, compliance, and peace of mind.

- Feel confident knowing your equipment meets rigorous safety and emission requirements

- Protect your community and environment from harmful pollutants

- Ensure your vehicles operate efficiently within legal limits

- Avoid costly fines and operational disruptions by staying compliant

Equipment Certification Processes

Ensuring that propane and gasoline equipment meet safety and environmental standards requires maneuvering a detailed certification process. You must verify that the equipment complies with specific regulations based on fuel type, which include safety measures for storage methods and operational controls. For propane, this involves demonstrating proper storage methods, such as secure tanks and leak prevention systems, and guaranteeing the equipment meets national safety standards. Gasoline equipment must also pass strict testing for flammability and emissions. Certification agencies review your designs, inspect storage methods, and conduct performance tests to confirm adherence. This process guarantees the equipment’s safety, environmental compliance, and readiness for use. Following these steps ensures your equipment meets all necessary legal requirements before deployment. Additionally, understanding cost variances can help you manage expenses associated with certification and equipment compliance more effectively.

Vehicle Compliance Checks

Vehicle compliance checks are essential to verify that equipment and vehicles meet safety and environmental standards before they’re allowed on the road. These checks ensure your vehicle’s fuel mixture aligns with emission standards, reducing pollution and avoiding fines. When inspecting, you’ll confirm the proper functioning of emission control systems, preventing harmful pollutants from escaping. Additionally, conducting dynamic communication exercises with your team can improve coordination during inspections, ensuring no detail is overlooked.

Stay alert to these critical points:

- Verifying the fuel mixture is correct for peak performance and compliance

- Confirming emission standards are met to avoid penalties

- Confirming safety features operate properly

- Checking for any leaks or malfunctions that could cause violations

Navigating Local and Federal Codes Effectively

Navigating local and federal codes can seem complex, but understanding how to do so effectively is essential for legal compliance and safe operation. You must stay informed on storage regulations and emission standards that apply to your setup. These codes ensure safety and environmental protection, preventing costly violations. To help clarify, consider this table:

| Code Level | Focus Area | Key Requirements |

|---|---|---|

| Local | Storage regulations | Proper container placement, labeling |

| Federal | Emission standards | Limits on emissions, reporting |

| Local & Fed | Safety and compliance | Permits, inspections |

| Local | Building codes | Ventilation, fire safety |

| Federal | Environmental impact | Pollution controls |

Staying current with these codes helps you avoid penalties and ensures your operation remains compliant and safe. Compliance standards are continually updated to reflect new safety and environmental concerns.

Common Mistakes and How to Avoid Them

Many operators overlook common pitfalls that can lead to costly violations or safety hazards. One major mistake is neglecting proper engine tuning, which affects fuel mixture and performance. Incorrect fuel mixture can cause inefficient operation, increased emissions, or engine damage. Avoid this by regularly checking your engine tuning settings to guarantee ideal performance.

Be cautious of these pitfalls:

- Ignoring proper fuel mixture ratios, risking engine failure

- Overlooking regular engine tuning, decreasing efficiency

- Failing to verify compliance with codes during maintenance

- Rushing repairs without understanding fuel and safety requirements

Addressing these issues proactively helps prevent violations, safety risks, and costly downtime. Staying vigilant about engine tuning and fueling practices ensures your operations are both safe and compliant.

Best Practices for Ensuring Legal and Safe Usage

To guarantee legal and safe usage of propane and gasoline, you must follow established regulations and manufacturer guidelines diligently. Understanding fuel type distinctions helps prevent mishandling and ensures compliance with emission regulations. Always verify that your equipment is rated for the specific fuel you’re using. Regularly inspect and maintain fuel containers, hoses, and fittings to prevent leaks. Keep thorough records of fuel purchases and usage to demonstrate compliance if needed. Use proper ventilation to reduce emissions and avoid buildup of hazardous fumes. Follow these best practices:

| Practice | Description | Why It Matters |

|---|---|---|

| Confirm fuel compatibility | Check manufacturer specs | Prevents damage and violations |

| Follow emission standards | Use compliant fuels and equipment | Ensures environmental safety |

| Proper storage | Store fuels in approved containers | Reduces leaks and accidents |

| Routine inspections | Regularly check for leaks and wear | Maintains safety and compliance |

| Documentation | Keep detailed fuel records | Supports legal adherence |

Making Informed Decisions Based on Your Specific Needs

Choosing the right fuel for your needs depends on understanding the specific advantages and limitations of propane and gasoline. To make an informed decision, assess your priorities through a fuel type comparison and analyze efficiency metrics. Consider these factors:

- Cost-effectiveness for long-term savings and budget control

- Availability and convenience to avoid interruptions

- Environmental impact if eco-friendliness matters

- Performance and runtime to guarantee your equipment runs smoothly

Frequently Asked Questions

How Do Fuel Container Sizes Impact Runtime and Efficiency?

Fuel container sizes directly impact your runtime and efficiency. Larger fuel capacity means you can operate longer without refueling, boosting productivity and convenience. However, bigger containers also increase storage impacts, making handling and transportation more challenging. Smaller tanks are easier to store and manage but require frequent refueling, which may reduce overall efficiency. Consider your operational needs to choose the right balance between fuel capacity and storage impacts for the most effective performance.

What Are the Long-Term Cost Differences Between Propane and Gasoline?

You’ll find propane often costs 30% less than gasoline over the long term, mainly due to fuel price fluctuations. Plus, propane typically requires lower maintenance, saving you money on repairs and upkeep. A maintenance cost analysis shows propane’s cleaner burn reduces engine wear, extending equipment lifespan. Over time, these factors make propane a more economical choice, helping you cut costs and avoid unexpected expenses associated with gasoline.

Are There Environmental Benefits Associated With Choosing One Fuel Over the Other?

Choosing propane offers notable environmental benefits, including emission reduction and a smaller carbon footprint compared to gasoline. Propane burns cleaner, producing fewer greenhouse gases and pollutants, which helps improve air quality. By selecting propane, you actively contribute to environmental protection and support sustainable practices. Gasoline, on the other hand, releases more pollutants, increasing your overall environmental impact. So, if you want a greener option, propane is the better choice.

How Do Seasonal Temperature Changes Affect Fuel Performance?

Think of your engine as a swimmer adjusting to changing water temperatures. When temperatures drop, propane’s fuel vaporization slows, making it harder to ignite, especially in cold weather. Conversely, higher engine temperatures in summer improve vaporization, boosting performance. Seasonal shifts impact fuel performance by altering vaporization rates, so you should consider these factors to guarantee ideal engine operation year-round. Proper adjustments help your engine run smoothly regardless of the season.

Can Equipment Designed for Gasoline Be Easily Converted to Propane?

You can convert equipment designed for gasoline to propane, but you need to prioritize fuel conversion and safety considerations. It involves installing a conversion kit, adjusting or replacing carburetors, and guaranteeing proper regulators and valves. Always follow manufacturer instructions and local codes. Consulting a professional ensures the conversion is safe and compliant, helping you avoid hazards and maintain maximum performance. Properly converted equipment offers reliable operation with propane.

Conclusion

By understanding the differences between propane and gasoline, you can make smarter choices for your equipment. For example, a small business switched to propane for its generators and saw longer runtime and lower emissions, all while staying compliant. Keep safety, regulations, and your specific needs in mind, and you’ll avoid costly mistakes. When you stay informed and follow best practices, you’ll guarantee legal, safe, and efficient operation every time.