Using dual fuel systems boosts efficiency and offers operational flexibility, allowing you to switch fuels based on availability and cost. However, safety risks like leaks and improper installation require careful planning. Make certain your setup includes certified components, regular inspections, and proper ventilation. Maintaining safety protocols and emergency plans helps protect personnel and equipment. To maximize benefits while minimizing risks, follow best practices—more details to guide your safety and operational success await.

Key Takeaways

- Prioritize regular inspection and certified detection devices to prevent leaks and ensure safe operation of dual fuel systems.

- Maintain proper ventilation and airflow management to prevent dangerous gas buildup during fuel switching or system faults.

- Follow strict installation protocols with qualified technicians to ensure secure connections, proper sealing, and adherence to safety standards.

- Conduct routine maintenance, safety audits, and keep detailed documentation to quickly identify and address potential hazards.

- Train staff on emergency shutdown procedures, safety protocols, and proper response plans to protect personnel and equipment during incidents.

Understanding the Core Benefits of Dual Fuel Systems

Understanding the core benefits of dual fuel systems is essential if you’re considering their use. One major advantage is improved fuel efficiency, allowing you to switch between fuel sources based on availability and cost. This flexibility helps reduce overall fuel expenses and minimizes downtime due to fuel shortages. Additionally, system versatility is a key benefit; dual fuel setups can adapt to different operational needs, whether you’re running a generator, vehicle, or industrial equipment. This adaptability ensures continuous operation in various environments. By combining fuels, you can optimize performance, extend equipment lifespan, and enjoy greater control over fuel consumption. Incorporating juice recipes and mixes can also inspire innovative ways to utilize alternative energy sources for sustainable living. Overall, these benefits make dual fuel systems a strategic choice for those aiming to boost efficiency and operational flexibility.

Assessing the Potential Risks and Safety Concerns

You need to prioritize gas leak prevention by regularly inspecting connections and using proper detection devices. Ensuring proper ventilation is vital to avoid dangerous buildup of fumes and maintain safe operation. Addressing these safety concerns helps protect you and your property from potential hazards. Regular maintenance and monitoring can also prevent unnoticed leaks that might lead to serious accidents, especially when dealing with gas detection devices.

Gas Leak Prevention

Have you ever considered how easily a gas leak can occur in dual fuel systems? It’s essential to stay alert to signs like a gas smell, which often indicates a leak. Regular leak detection is critical for safety; even small leaks can pose serious risks. Always inspect connections, valves, and hoses for damage or corrosion. If you notice a strong gas odor, turn off the system immediately and ventilate the area. Use certified gas detectors to monitor for leaks continuously. Maintaining a proactive approach helps prevent accidents caused by undetected leaks. Remember, early detection saves lives and reduces damage. Don’t ignore the importance of routine inspections and prompt action when you suspect a leak. Staying vigilant is your best defense against potential hazards. Incorporating protective styling practices can also help prevent damage to system components and reduce leak risks.

Proper Ventilation Practices

Proper ventilation is vital for maintaining safety in dual fuel systems, especially when dealing with potential gas leaks. You need to focus on airflow optimization to prevent the buildup of dangerous gases and ensure fresh air circulates effectively. Good exhaust management is essential; it directs combustion byproducts safely outside, reducing the risk of indoor hazards. Regularly inspect vents and ducts to guarantee unobstructed airflow and proper functioning. Avoid blockages or leaks that can compromise ventilation efficiency. Maintain a balanced airflow to prevent pressure imbalances that could lead to leaks or inefficient combustion. Proper ventilation not only minimizes health risks but also enhances system performance and safety. Additionally, understanding the family background of the system’s design and installation can provide insights into potential vulnerabilities and maintenance needs. By prioritizing airflow optimization and exhaust management, you create a safer environment and prolong your system’s lifespan.

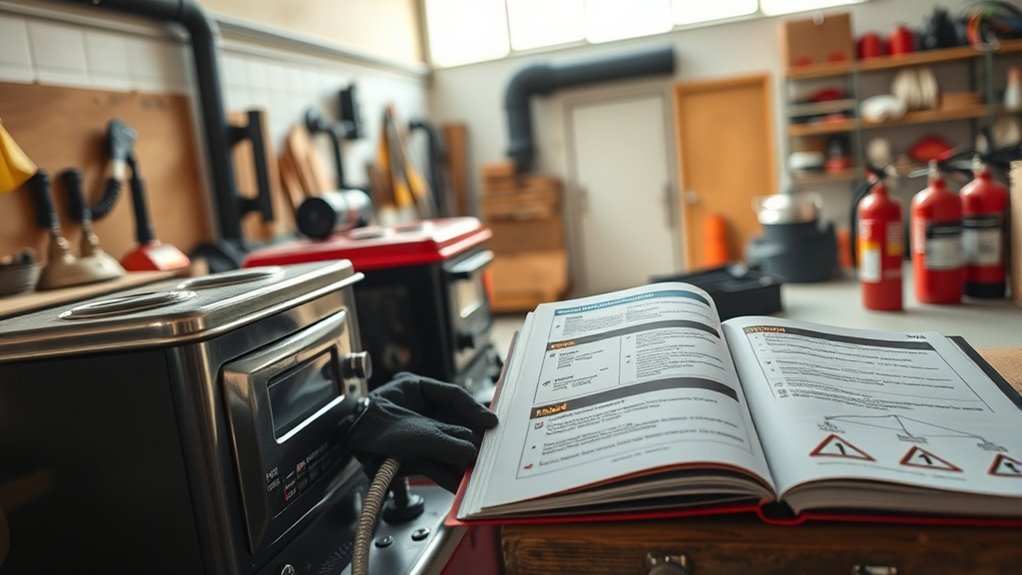

Key Components and Their Safety Features

Understanding the key components of a dual fuel system is essential for guaranteeing safety and reliable operation. You should pay close attention to component durability, as high-quality parts withstand daily wear and tear, reducing failure risks. Safety certifications are equally important; certified components meet industry standards and have been tested for safety performance. For example, valves, regulators, and sensors with proper certifications help prevent leaks, overpressure, or malfunctions that could lead to dangerous situations. Regularly inspecting these components ensures they remain in good condition, maintaining safety and efficiency. Additionally, system monitoring tools can provide real-time alerts to identify potential issues early, further enhancing safety measures. Remember, well-maintained, certified parts are your best defense against potential hazards, providing peace of mind knowing your dual fuel system operates safely under various conditions.

Best Practices for Safe Design and Installation

To guarantee safety, you need to follow proper code compliance during design and installation. Using skilled technicians helps prevent common mistakes and guarantees everything is set up correctly. Prioritizing these practices keeps your dual fuel system operating safely and efficiently. Incorporating installation planning resources can further ensure adherence to safety standards and streamline the process.

Proper Code Compliance

Ensuring code compliance is essential for the safe design and installation of dual fuel systems. When you follow local, state, and national codes, you help guarantee system safety, efficiency, and durability. Proper compliance also enhances fuel efficiency by ensuring systems operate as intended, reducing waste and unnecessary consumption. Additionally, adhering to codes minimizes environmental impact by preventing leaks, emissions, and hazards that could harm the surroundings. Regularly consult relevant standards, such as the National Electrical Code (NEC) and local building regulations, to ensure your setup meets all requirements. Proper code compliance not only protects your investment but also promotes a safe environment for users and the community. Staying current with updates and best practices ensures your dual fuel system operates effectively and responsibly. Checking for discoloration or separation in fuel components can help identify potential issues early, ensuring ongoing safety and performance.

Skilled Installation Techniques

Proper code compliance sets the foundation for safe dual fuel system installation, but executing those standards correctly requires skilled techniques. You need precise work to ensure ideal system integration, which directly impacts fuel efficiency and reliability. Use proper sealing and secure connections to prevent leaks and hazards. Accurate wiring and calibration are essential for seamless operation between fuel sources. Pay close attention to venting and safety controls to avoid dangerous buildup or malfunctions. When installing components, follow manufacturer instructions carefully and verify compatibility. Skilled technicians also ensure proper sizing of equipment, maximizing fuel efficiency while maintaining safety. Incorporating lifestyle considerations into the planning process helps optimize the overall safety and functionality of the system. Consistent testing throughout the installation process confirms the system functions correctly and safely. Mastering these techniques guarantees a reliable, efficient dual fuel setup that meets all safety standards.

Maintenance and Inspection Protocols to Ensure Safety

Regular maintenance and thorough inspections are essential to keep dual fuel systems operating safely and efficiently. You should regularly check fuel compatibility to prevent system damage or safety hazards. Confirm all components meet safety certification standards to verify their reliability. Routine inspections help identify leaks, corrosion, or wear that could compromise safety. Keep an eye on pressure levels and valve functionality to prevent malfunctions. Additionally, verify that safety devices, like shutoff valves and sensors, are working correctly. Document all maintenance activities for ongoing safety assurance. Incorporate these key practices to maintain compliance and reduce risks. Proper protocols not only protect your equipment but also safeguard lives and ensure ideal system performance. Conducting regular safety audits can further identify potential vulnerabilities before they lead to hazards.

Emergency Preparedness and Response Strategies

Being prepared for emergencies is essential to minimizing risks and ensuring a swift response when incidents occur. You should develop clear emergency response plans that prioritize generator safety, including protocols for power failures or fuel leaks. Regularly practicing emergency drills helps you identify weaknesses and improve reaction times. During drills, focus on safe shutdown procedures, proper evacuation routes, and communication strategies. Ensuring all staff understand their roles reduces confusion during real emergencies. Keep emergency supplies and safety equipment readily accessible, and review your plans periodically to adapt to changing circumstances. Incorporating training on equipment operation into your emergency preparedness ensures staff are confident in handling unexpected situations. Prompt, well-coordinated responses can prevent escalation and protect lives. Prioritizing generator safety during emergencies minimizes hazards and maintains critical operations, even under stressful conditions.

Balancing Cost Savings With Safety Considerations

Balancing cost savings with safety considerations requires careful planning and ongoing evaluation. You need to weigh fuel pricing advantages against potential safety risks, ensuring that cost-cutting doesn’t compromise standards. Staying informed about environmental impact helps you choose fuels that lower emissions while maintaining safety. By regularly reviewing operational data, you can optimize fuel use without jeopardizing safety protocols. Prioritizing training ensures your team handles dual fuel systems responsibly.

Careful planning and ongoing review balance cost savings with safety and environmental responsibility.

- Monitor fuel pricing trends to identify cost-effective options

- Assess environmental impact to align with sustainability goals

- Implement safety audits to catch potential hazards early

- Keep staff trained on safety procedures for fuel switching

- Regularly review safety protocols as technology evolves

Frequently Asked Questions

How Do Dual Fuel Systems Impact Overall Household Safety?

Dual fuel systems can improve household safety by providing reliable power, but you need to stay vigilant about fire hazards and ventilation safety. Proper installation and regular maintenance reduce fire risks, while ensuring adequate ventilation prevents dangerous buildup of gases. Always follow safety guidelines, keep detectors functional, and schedule professional inspections. By doing so, you minimize potential hazards and keep your home safe while enjoying the benefits of dual fuel systems.

What Are Common Safety Errors During Dual Fuel System Installation?

You might unknowingly fall into installation hazards or make maintenance errors that jeopardize safety. Common mistakes include improper venting, incorrect wiring, or neglecting regular inspections. These errors can lead to gas leaks, carbon monoxide buildup, or fire risks. Stay vigilant, follow manufacturer instructions, and schedule professional checks. Avoid shortcuts during installation and maintenance to guarantee your dual fuel system remains safe and reliable, protecting everyone in your household.

How Can Users Identify Early Signs of Safety Issues?

You can identify early safety issues by paying attention to warning signs like unusual smells, leaks, or inconsistent system performance. Regular safety inspections are essential; they help catch problems before they escalate. If you notice any strange noises, corrosion, or gas odors, shut off the system and consult a professional. Staying vigilant and conducting routine inspections guarantee your dual fuel system remains safe and reliable.

Are There Specific Safety Certifications for Dual Fuel System Components?

Think of safety certifications for dual fuel system components as a trusty lighthouse guiding your way. You should look for certification standards like UL, FM, or CSA, which guarantee your equipment meets strict safety protocols. These standards act like a safety net, catching potential hazards before they become problems. Always verify that your components have proper certifications, giving you peace of mind and keeping your system operating safely and efficiently.

How Does Weather Influence Safety Risks in Dual Fuel Systems?

Weather hazards like extreme cold, heat, or humidity can considerably impact your dual fuel system’s safety. Climate considerations affect how components operate, increasing risks of leaks, corrosion, or system failure. During storms or heavy rain, water intrusion may cause electrical hazards or corrosion, while freezing temperatures can lead to fuel line blockages. Always monitor weather conditions, perform regular maintenance, and adapt safety protocols to minimize weather-related risks.

Conclusion

Think of dual fuel systems as a carefully balanced dance between power and safety. When you understand their benefits and respect their risks, you’re guiding a reliable vessel through calm and storm alike. By prioritizing safety features and regular maintenance, you’re anchoring your operation in confidence. Remember, the true strength lies in harmony—where cost savings and safety sail together, you’re steering toward a secure and efficient future.