To properly store fuel with stabilizers, you must carefully calculate the right amount of stabilizer based on your fuel volume and follow the manufacturer’s instructions. Measure accurately using appropriate tools, and consider storage duration to prevent fuel degradation. Keep track of your consumption rate and adjust stabilizer levels as needed. If you want to guarantee your fuel stays fresh and your equipment runs smoothly, understanding these calculations is essential—keep exploring for more detailed guidance.

Key Takeaways

- Always measure stabilizer-to-fuel ratio precisely according to manufacturer instructions to prevent under- or over-treatment.

- Calculate fuel volume accurately, considering temperature effects on fuel density for proper stabilizer dosing.

- Determine storage duration limits based on fuel type and stabilizer compatibility to avoid degradation.

- Regularly monitor stabilizer levels and adjust based on storage conditions and fuel stability indicators.

- Convert measurement units correctly and use calibrated tools to ensure precise fuel and stabilizer calculations.

Calculating the Right Amount of Fuel Stabilizer Needed

Before adding fuel stabilizer, it’s essential to determine the correct amount needed for your fuel. Proper calculation depends on the fuel quality and the stabilizer’s recommended dosage. Check the product label for precise instructions, as different brands may require varying amounts. Using too little stabilizer can lead to inadequate protection and fuel degradation, while too much might cause issues with additive compatibility and engine performance. Always measure carefully, considering the volume of fuel you’re storing. It’s best to err on the side of accuracy to guarantee maximum preservation. Understanding offensive security measures and following the manufacturer’s guidelines, you can effectively determine the right amount of stabilizer, ensuring your fuel remains fresh and engine-ready when you need it.

Determining Storage Duration and Fuel Stability Limits

How long your fuel remains stable depends on its type, storage conditions, and added stabilizers. Fuel degradation occurs over time due to factors like oxygen exposure, temperature fluctuations, and moisture, which can accelerate breakdown. To determine storage duration, consider the fuel’s stability limits, often specified by manufacturers or tested through stability charts. Proper additive compatibility is essential; using incompatible stabilizers can speed up fuel degradation or harm your equipment. Regularly check for signs of deterioration, such as changes in color or smell. Knowing these limits helps you plan refueling schedules and avoid stale fuel issues. Additionally, AI safety measures are crucial in developing reliable fuel storage solutions that prevent potential hazards. By understanding fuel stability and ensuring additive compatibility, you can maximize storage time without risking engine problems or fuel quality loss.

Volume Conversion and Measurement Accuracy for Storage

Accurate volume measurement is key to maintaining fuel quality and ensuring proper storage. To do this effectively, you need to understand fuel density, which varies with temperature and affects volume readings. When measuring, always account for this variation to avoid overfilling or underfilling your container. Knowing your container capacity helps prevent spills and guarantees safe storage. Use precise tools like calibrated gauges or flow meters for better accuracy. Convert measurements properly if you’re using different units, such as gallons to liters, to maintain consistency. Small errors in volume measurement can lead to fuel degradation or safety issues. By paying close attention to fuel density and container capacity, you can achieve more accurate measurements and optimize your fuel storage practices. Additionally, understanding Angel Numbers related to transformation and readiness can provide spiritual insight into the importance of precise and careful measurement practices.

Estimating Fuel Consumption and Replenishment Schedules

Estimating your fuel consumption effectively helps you plan when to replenish your supply and avoid running out unexpectedly. To do this, track your usage patterns and consider factors like engine efficiency and storage conditions. Incorporate fuel additives into your calculations, as they can extend fuel shelf life and improve performance, reducing the frequency of replenishment. Use appropriate storage containers that prevent evaporation, leaks, and contamination, which can skew your estimates. Regularly review your consumption rates to adjust your replenishment schedule accurately. Additionally, understanding the properties of organic and natural juices can help you identify any potential contamination risks in your storage methods. By understanding your fuel needs and the impact of additives and storage solutions, you can guarantee your fuel supply remains stable and ready when you need it, minimizing waste and maximizing efficiency.

Monitoring and Adjusting Stabilizer Levels Over Time

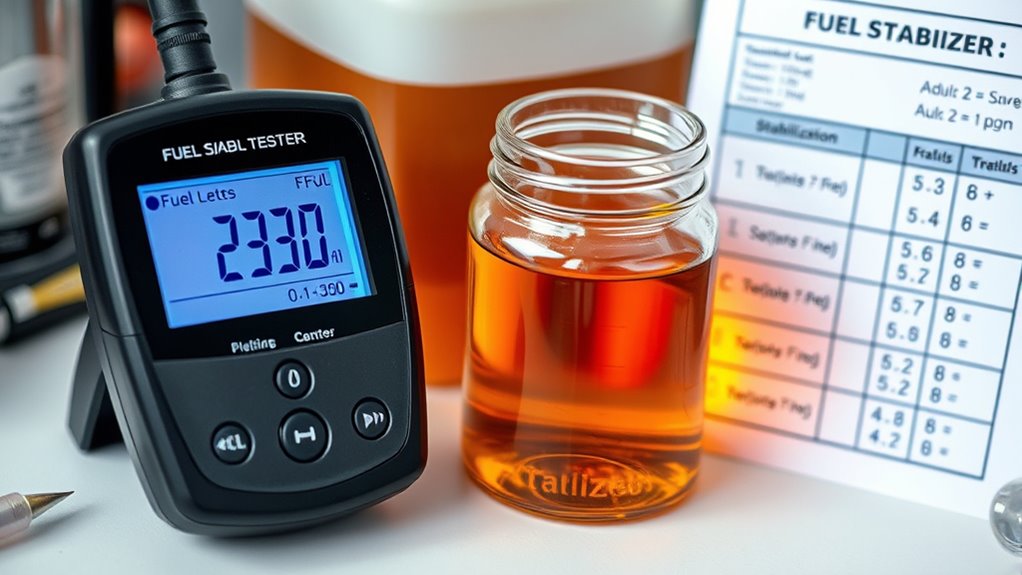

Regularly monitoring your stabilizer levels guarantees that your fuel remains protected from degradation over time. Check the stabilizer concentration periodically to make certain it remains within the recommended range, especially if you’re storing fuel for extended periods. Be aware of additive compatibility, as certain stabilizers may react differently depending on the fuel type, potentially reducing effectiveness. Temperature effects also play a vital role; high temperatures can accelerate fuel deterioration and destabilize additives, so adjust stabilizer levels accordingly. Use a simple testing method or a fuel stability kit to verify levels without guesswork. If you notice changes or if storage conditions fluctuate, add more stabilizer to maintain ideal protection. Consistent monitoring helps prevent issues like phase separation or gum formation, preserving your fuel’s quality over time. Additionally, understanding how air quality can influence fuel storage conditions can help optimize your stabilization efforts.

Frequently Asked Questions

How Does Temperature Affect Fuel Stabilizer Effectiveness Over Time?

Temperature impacts fuel stabilizer effectiveness by affecting temperature stability and storage conditions. When temperatures fluctuate or rise, fuel can degrade faster, reducing stabilizer efficiency. Cold temperatures generally slow chemical reactions, helping preserve fuel longer, but extreme cold can cause condensation or freezing issues. To guarantee maximum effectiveness, store fuel in a cool, stable environment, minimizing temperature variations that can compromise fuel quality over time.

Can Different Fuel Types Require Different Stabilizer Formulations?

Think of fuel types like different musical instruments needing specific tuning. You’ll find that some fuels require unique stabilizer formulations due to their fuel compatibility. When choosing an additive, consider these differences to guarantee peak performance and preservation. Using the right stabilizer for each fuel type prevents issues like corrosion or phase separation, making your storage reliable. Always check manufacturer guidelines to select the proper stabilizer formulation tailored to your fuel.

What Safety Precautions Should I Follow When Handling Stabilizers?

When handling stabilizers, you should always follow handling precautions like wearing gloves and eye protection to avoid skin and eye contact. Guarantee good ventilation to prevent inhaling fumes. Store stabilizers in a cool, dry place away from heat sources and open flames to maintain storage safety. Keep containers tightly sealed and label them clearly. Always read the manufacturer’s instructions for specific safety guidelines, and never mix different stabilizers.

Are There Environmental Impacts of Using Fuel Stabilizers Long-Term?

Using fuel stabilizers long-term can raise environmental concerns, as certain chemicals may break down slowly, potentially contaminating soil and water. You should be aware that some stabilizers contain additives that persist in the environment, which could harm wildlife or disrupt ecosystems. To minimize impact, always follow disposal guidelines and opt for eco-friendly options when available, ensuring responsible use and reducing long-term environmental effects.

How Can I Dispose of Unused or Expired Fuel Stabilizers Safely?

You should never pour unused or expired fuel stabilizers down the drain; it’s like dumping poison into a crystal-clear lake. Instead, follow proper chemical disposal protocols. Contact your local waste management or hazardous waste facility for safe disposal options. Some places offer recycling methods or designated drop-off sites. Always store and dispose of chemicals responsibly to protect the environment and prevent potential health hazards.

Conclusion

By mastering these calculations, you’ll keep your fuel fresh like a well-tuned engine. Remember to measure carefully, monitor regularly, and adjust as needed—it’s like steering a ship through calm waters. Proper storage and stabilizer use guarantee your fuel stays reliable and safe, saving you time and money in the long run. Keep these steps in mind, and you’ll navigate fuel storage with confidence, making it as smooth as a seamless ride.