When comparing noise levels at idle versus full load, you’ll notice a clear increase as equipment works harder. At idle, noise is minimal because components vibrate less and spin slower. As you push the system to full load, vibrations and motor speeds rise, amplifying sounds. This change impacts both sound quality and comfort. To understand how equipment manages this shift, keep exploring the details behind load-related noise dynamics.

Key Takeaways

- Noise levels are lower during idle operation due to minimal vibrations and slower moving parts.

- Full load increases noise as faster spinning components and higher motor speeds generate more sound.

- Vibrations and mechanical stress escalate with load, amplifying noise output during full capacity.

- Proper mounting and vibration damping help reduce noise at both idle and full load states.

- Regular maintenance and acoustic insulation mitigate noise escalation as equipment approaches full load.

Understanding how noise levels change with different loads is vital if you want to monitor and manage equipment noise effectively. When equipment operates at idle, it often produces less noise, but that doesn’t mean it’s silent. Hardware vibrations tend to be minimal during idle states, resulting in quieter operation overall. However, even at low loads, vibrations can still cause a certain amount of noise, especially if the equipment isn’t properly mounted or if the components are loose. To minimize this, implementing effective acoustic insulation becomes essential. Acoustic insulation helps dampen the sound generated by vibrations, preventing noise from propagating through walls or enclosures. When you focus on improving insulation around idle equipment, you’re better equipped to reduce background noise in your workspace, making it more comfortable and less distracting. Additionally, AI-powered analytics can assist in monitoring noise patterns over time, enabling predictive maintenance and further noise reduction strategies.

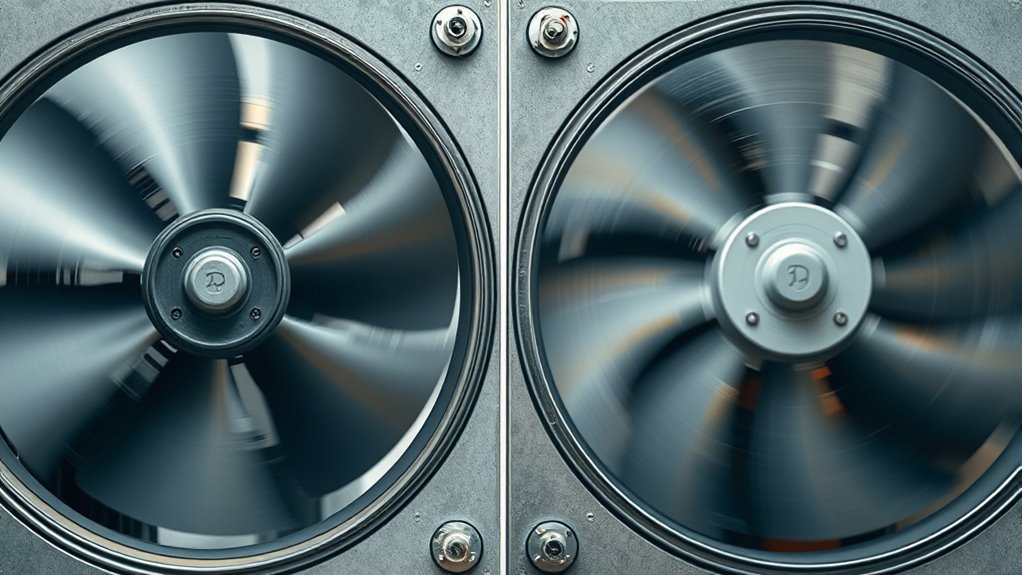

As the load increases toward full capacity, you’ll notice a rise in noise levels. This uptick is primarily due to increased hardware vibrations. When machinery works harder, internal components spin faster, motors run at higher speeds, and mechanical parts experience more stress. All these factors contribute to amplified vibrations that generate additional noise. If left unchecked, these vibrations can also cause wear and tear, potentially leading to more notable noise issues over time. Consequently, managing hardware vibrations becomes increasingly important at higher loads. Properly balancing rotating parts, securing loose components, and using vibration-damping mounts can considerably cut down on the noise produced during full load operation. Good acoustic insulation around critical parts can absorb the excess sound, preventing it from spreading throughout your facility.

You should also consider how the design of your equipment influences noise levels at different loads. Some machines are built with noise reduction features, such as sound enclosures or vibration isolators. These features can help maintain a relatively consistent noise level, even as load conditions change. Regular maintenance is another key factor—ensuring that bearings, belts, and other moving parts are in good condition helps reduce unnecessary vibrations and noise. By paying attention to these details, you can better control noise pollution and create a safer, more comfortable environment.

Frequently Asked Questions

How Do Ambient Noise Levels Affect Measurements?

Ambient noise levels can considerably impact your measurements by introducing background sounds that distort the actual noise you’re trying to assess. When ambient noise is high, it lowers measurement accuracy because it becomes harder to distinguish between the noise source and background sounds. To guarantee precise results, you should minimize ambient noise or subtract its influence during analysis, allowing for more accurate and reliable noise measurements.

What Tools Are Best for Measuring Noise Accurately?

You should use a precision sound level meter with proper sound calibration to guarantee measurement accuracy. For example, in a factory, calibrated equipment helped identify noise peaks during full load operations. Choose tools with adjustable weighting filters and frequency response settings. Regular calibration checks maintain accuracy over time. This guarantees reliable data, making it easier to assess noise levels at idle versus full load, and implement effective noise control measures.

Are There Industry Standards for Acceptable Noise Levels?

Yes, there are industry standards for acceptable noise levels, which guide your standards compliance and noise mitigation efforts. Organizations like OSHA and ISO set these limits to protect workers and ensure equipment operates quietly. You should regularly compare your equipment’s noise levels against these standards, implement noise mitigation strategies if needed, and stay updated on any changes to uphold compliance and promote a safer, more comfortable environment.

How Does Distance From the Source Impact Perceived Noise?

The distance from the source greatly impacts how you perceive noise because sound reflection and source attenuation play key roles. As you move farther away, sound waves spread out and reflect off surfaces, reducing the perceived volume. Source attenuation also causes noise levels to decrease with distance. So, the farther you are, the quieter it seems, thanks to these factors that diminish sound energy before it reaches your ears.

Can Noise Levels at Different Loads Affect Equipment Lifespan?

Yes, noise levels at different loads can impact equipment durability. Higher noise often indicates increased vibrations and stress, which can accelerate wear and tear. To protect your equipment, implement noise mitigation strategies like proper insulation and damping. By reducing noise, you not only improve the environment but also extend your equipment’s lifespan, ensuring it operates efficiently longer and minimizes costly repairs or replacements over time.

Conclusion

When comparing noise levels at idle and full load, you’ll notice the difference is like night and day. Full load operation tends to crank up the volume, making your equipment sound like a busy city street, while idle mode is much quieter—more like a whisper. Understanding these differences helps you plan for a quieter workspace or home. So, next time you hear the hum, remember, it’s just the machine’s way of saying it’s working hard.