To guarantee safe and reliable parallel cable use, always inspect your cables for damage before connecting them, keep them away from water or moisture, and select the right cable type for your devices. Handle cables gently to avoid damage, store them properly when not in use, and avoid placing them in high-traffic areas. Using protective devices and replacing worn or damaged cables promptly keeps your setup secure. If you continue, you’ll discover more expert safety tips.

Key Takeaways

- Regularly inspect and replace damaged cables to prevent shorts, fires, and equipment failure.

- Handle cables gently, avoid excessive bending, and secure connections properly to maintain physical integrity.

- Use the correct cable type for your equipment and ensure connections are secure without over-tightening.

- Disconnect power before connecting or disconnecting cables and keep cables away from water or moisture.

- Educate personnel on safety protocols, conduct routine checks, and store cables properly to ensure overall safety.

Always Inspect Cables Before Use

Before plugging in a cable, you should always inspect it thoroughly. Check for visible damage like cuts, frays, or exposed wiring that could pose safety risks. Proper cable labeling helps you quickly identify the right cables, reducing confusion and potential misuse. Good cable management ensures cables are organized, minimizing tangling and accidental damage. If you notice any wear or irregularities, don’t force the connection; replace the damaged cable immediately. A quick inspection can prevent electrical shorts, fires, or equipment failure. Keep your workspace safe by maintaining a routine of checking cables before use. Properly labeled and well-managed cables make inspections faster and more effective, ensuring safety remains a top priority every time you connect your devices. Incorporating natural techniques for seed production can also improve the overall quality and safety of your agricultural equipment maintenance.

Keep Cables Away From Water and Moisture

Water and moisture are one of the biggest hazards to cable safety, so always keep your cables dry and away from wet areas. Water exposure can cause short circuits, electrical shocks, and damage to your equipment. Moisture risk increases if cables are left in damp environments or exposed to spills and leaks. To prevent accidents, avoid running cables through areas prone to water, such as near sinks, windows, or outdoor spaces. Use protective covers or enclosures if you must run cables in humid or moist conditions. Regularly inspect your cables for signs of moisture, like corrosion or discoloration. Ensuring proper cable insulation helps prevent water ingress and enhances safety. Keeping cables dry not only prolongs their lifespan but also ensures safe and reliable operation, reducing the chance of electrical hazards caused by water exposure.

Use the Correct Cable Type for Your Equipment

Using the right cable type guarantees your equipment operates safely and efficiently. Make sure the cable’s specifications match your device’s requirements to prevent damage. Choosing the correct cable protects your gear and maintains peak performance. Additionally, understanding specific tuning techniques can help optimize your vehicle’s performance without compromising safety.

Match Cable Specifications

Choosing the right cable type is essential to guarantee your equipment functions safely and efficiently. Always check the cable specifications to ensure compatibility with your devices. Matching cables with the correct specifications prevents connection issues and potential damage. For example, using a cable with the proper data transfer rate or power capacity ensures reliable performance. Mismatched cables can cause slowdowns, signal loss, or electrical faults. Take the time to verify that your cables meet the manufacturer’s recommendations for your specific equipment. Using mismatched cables not only risks damaging your devices but also compromises safety. Always select cables designed for your setup, paying close attention to their specifications, so you maintain a safe and effective connection. Proper matching is key to a safe, trouble-free operation. Additionally, understanding divorce statistics and regional legal resources can help you navigate complex situations more effectively.

Prevent Equipment Damage

Matching cables with the correct specifications helps prevent damage to your equipment. Using the right cable type ensures compatibility, reducing the risk of electrical overloads or shorts. Proper grounding techniques are essential—grounding helps dissipate static and excess voltage, protecting sensitive components. Always verify cable labeling to confirm it matches your device’s requirements; mislabeling can lead to improper connections and potential damage. Avoid using generic or damaged cables, which can cause short circuits or data errors. Regularly inspect your cables for wear and tear, replacing them as needed. Additionally, choosing the appropriate cable type that is designed for your specific equipment can significantly improve safety and performance. By choosing the correct cable type, applying proper grounding techniques, and paying attention to labeling, you safeguard your equipment from costly damage and ensure safe, reliable operation.

Avoid Overloading Parallel Ports

Overloading parallel ports can cause serious damage to your equipment and compromise safety. When you connect too many devices or draw excessive power, you risk a power surge that can fry internal components. Additionally, overloading increases electromagnetic interference, which can disrupt signal integrity and affect nearby devices. To prevent these issues, always check the port’s maximum capacity and avoid plugging in more devices than recommended. Use powered hubs if you need to connect multiple peripherals, and ensure your power supply can handle the load. Regularly inspecting your cables and connections helps prevent accidental overloads. Staying within the port’s limits protects your equipment, reduces safety hazards, and guarantees reliable operation over time. Being aware of power management principles can further help prevent overloads and maintain system safety.

Handle Cables Gently to Prevent Damage

To keep your cables functioning properly and guarantee safety, you need to handle them with care. Proper cable handling involves gentle manipulation—avoiding yanking, twisting, or pulling on the cable. When disconnecting or connecting, grip the plug firmly rather than pulling on the cable itself. This prevents internal wire breaks and connector damage. Keep cables free from sharp bends or kinks, which can weaken the internal wires. Always support the cable’s weight rather than letting it hang freely, and avoid stepping on or crushing cables. Regularly inspect for signs of wear or damage, and replace worn cables immediately. Gentle handling extends the lifespan of your parallel cables, reduces the risk of electrical shorts, and helps ensure safe, reliable connections over time. Additionally, understanding the importance of water efficiency can help prevent unnecessary strain on your plumbing and electrical systems.

Secure Connections Firmly but Not Forcibly

Make sure connectors are properly tightened so your cable stays secure. Don’t over-tighten, as it can damage the pins or the port. Always check for a firm, snug fit to ensure safety and reliable connection. Additionally, proper cable management can help prevent accidental disconnections and damage. community engagement

Properly Tighten Connectors

When tightening connectors, it’s important to find the right balance between securing the connection and avoiding damage. Proper connector maintenance relies on effective tightening techniques that ensure a reliable connection without stripping threads or crushing components. Over-tightening can cause damage, while under-tightening leads to poor contact. Use a consistent approach: tighten until the connector feels snug, then give it a slight additional turn. Here’s a quick guide:

| Step | Action | Tip |

|---|---|---|

| 1 | Hand-tighten first | Feel for resistance |

| 2 | Use a tool if needed | Avoid excessive force |

| 3 | Check stability | Confirm firm, not tight |

| 4 | Inspect connections | Maintain proper connector maintenance |

Additionally, understanding the latest advancements in machine learning can help improve maintenance procedures through predictive analytics. Follow these techniques for secure, damage-free connections every time.

Avoid Over-tightening Force

While ensuring a solid connection is essential, applying too much force can cause damage to connectors and threads. Over-tightening may strip threads or crack plastic components, leading to costly repairs. To avoid this, consider these tips:

- Check the cable length; longer cables may require a slightly firmer grip, but never force beyond resistance.

- Use the connector color as a guide—some colors indicate specific torque levels, so don’t ignore these cues.

- Tighten until the connection feels firm but not forced; if it resists or feels overly tight, loosen slightly.

- Remember that 16PF traits can influence how individuals approach tasks like cable connections, emphasizing the importance of careful handling and awareness of personal tendencies to avoid damage.

Check for Secure Fit

Ensuring a secure connection requires more than just fitting the cable into the port; you need to verify that it’s firmly seated without applying excessive force. Check that the cable doesn’t wobble or easily slip out. Pay attention to cable aesthetics—well-designed cables often have clear, snug fittings. Use color coding to quickly identify connections and confirm proper placement.

| Cable Type | Color Coding |

|---|---|

| Parallel Cable A | Blue for Data Line |

| Parallel Cable B | Red for Power |

| Universal Cable | Green for Ground |

A secure, firm fit ensures reliable data transfer and safety. Remember, a properly seated cable maintains both functionality and safety without risking damage.

Avoid Bending or Twisting Cables Excessively

Bending or twisting cables excessively can damage their internal wiring and compromise safety. To maintain cable flexibility and guarantee longevity, avoid exceeding the bending limits specified by the manufacturer. Over-bending can cause internal breaks, increasing the risk of shorts or failure.

Here are three tips to prevent damage:

- Keep bends gentle and within the recommended radius to protect cable integrity.

- Use cable organizers to prevent unnecessary twisting or sharp angles.

- Regularly inspect cables for signs of wear or stress, replacing damaged ones immediately.

Disconnect Power Before Connecting or Disconnecting

Before connecting or disconnecting parallel cables, always turn off and unplug the power source. This prevents accidental electrical shocks and damage. Proper grounding practices are essential; verify your equipment is properly grounded to avoid static buildup or electrical faults. Before handling cables, double-check that they’re correctly labeled, so you connect the right ports and avoid miswiring. Disconnecting power before making changes reduces the risk of short circuits or sparks that could harm you or damage your equipment. Remember, working on live circuits is dangerous and can cause serious injury. Always follow a safe procedure: power down, unplug, verify grounding, and confirm cable labeling. These steps keep your workspace safe and ensure that you handle parallel cables correctly and securely.

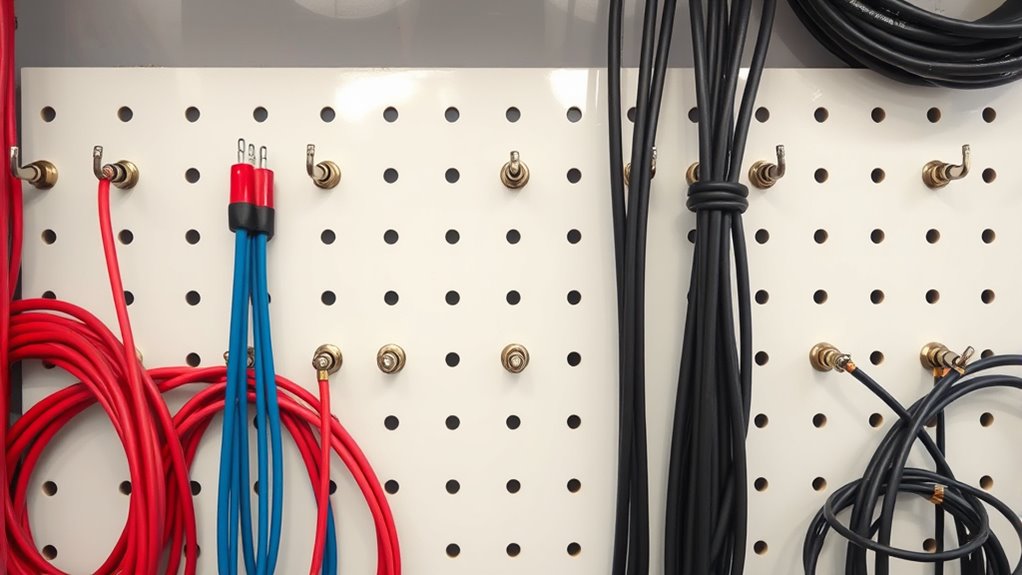

Store Cables Properly When Not in Use

Storing cables properly when not in use helps prevent damage and guarantees they remain functional. Good cable organization minimizes tangles and reduces wear. Using effective storage solutions keeps your cables accessible and in good shape.

Here are some tips to store your cables securely:

- Coil cables gently to avoid kinks and stress points.

- Use cable ties or Velcro straps for neat organization.

- Store cables in designated containers or drawers to prevent dust and damage.

Proper storage not only extends the lifespan of your cables but also makes setup quicker. Avoid leaving cables tangled or exposed to heavy objects. Implementing simple storage solutions ensures your cables stay in top condition and ready when needed.

Keep Cables Out of High-Traffic Areas

You should always keep cables out of high-traffic areas to prevent accidents. Make sure walkways are clear and use cable covers to secure cords safely. Taking these steps helps protect everyone from trips and equipment damage.

Clear Walkways Always

Keeping walkways clear is essential for cable safety, especially in high-traffic areas. When cables cross paths with foot traffic, it increases the risk of trips and damage. To maintain safety and cable aesthetics, always route cables away from busy zones. Use these strategies:

- Secure cables along walls or ceilings to avoid cluttered walkways.

- Employ decorative cable covers where cables must cross open areas, blending safety with aesthetics.

- Regularly inspect and adjust cable placements to prevent tripping hazards and keep pathways unobstructed.

Use Cable Covers

Using cable covers is one of the most effective ways to keep cables out of high-traffic areas and prevent accidents. They improve cable management by securely holding cables in place and reducing tripping hazards. When installing cable covers, ensure they are thick enough to withstand foot traffic and are firmly anchored to the floor. Proper cable labeling helps identify cables quickly, making maintenance safer and more efficient. Clear labels prevent you from accidentally unplugging the wrong cord or damaging the setup during repairs. Regularly inspect the covers for wear or damage and replace them as needed. By combining cable covers with proper cable labeling and management, you create a safer environment that minimizes risks and keeps your workspace organized and accessible.

Use Protective Devices When Necessary

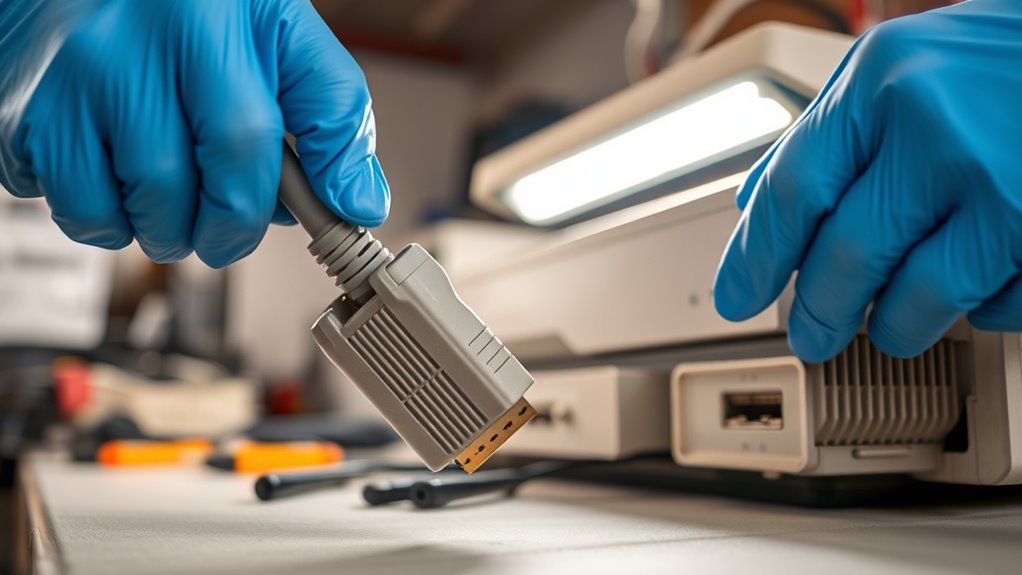

When working with parallel cables, wearing protective devices is essential to prevent injury and equipment damage. Proper protective gear minimizes risks, especially during troubleshooting or installation. Always use grounding techniques to prevent electrical shocks, ensuring safety for yourself and your tools. Here are three key protective devices to contemplate:

- Insulated gloves—protect your hands from electrical shocks and accidental contact.

- Safety goggles—shield your eyes from sparks, debris, or unexpected electrical discharges.

- Grounding mats—provide a safe path for stray currents, reducing the risk of electric shock.

Using these protective devices when necessary helps you stay safe and maintain the integrity of your equipment. Never skip protective gear, especially when working with live wires or uncertain conditions.

Regularly Replace Worn or Damaged Cables

Regularly replacing worn or damaged cables is essential because degraded insulation or visible wear can cause electrical failures or pose safety hazards. Over time, cable material can deteriorate, increasing the risk of short circuits or fires. Keep an eye on cables with frayed insulation, cracks, or exposed wires, and don’t hesitate to swap them out. Using proper color coding helps identify cables quickly and ensures you’re handling the correct ones safely. Consider this table:

| Cable Material | Color Coding |

|---|---|

| Rubber, PVC | Red, Blue, Green |

| Teflon, Silicone | Black, Yellow |

| Cloth-covered | White, Gray |

Regular checks and timely replacements keep your setup safe and reliable.

Frequently Asked Questions

Can Using the Wrong Cable Cause Equipment Damage?

Using the wrong cable can definitely cause equipment damage. Poor cable quality or mismatched connector compatibility can lead to voltage spikes, short circuits, or signal loss. When you use an incompatible or low-quality cable, it may not handle your device’s power needs properly, risking permanent damage. Always make certain your cable matches your equipment’s specifications and connectors to protect your devices and ensure safe, reliable operation.

What Are Signs of a Damaged Parallel Cable?

You’ll notice signs of a damaged parallel cable if the cable insulation looks frayed or cracked, which indicates wear and potential exposure of internal wires. Also, check for connector corrosion, where rust or discoloration appears on the connectors, leading to poor connections. These issues can cause signal loss or intermittent problems. Regularly inspecting your cable for insulation damage and corrosion helps prevent equipment damage and guarantees reliable performance.

How Often Should I Replace My Parallel Cables?

You should replace your parallel cables every 3 to 5 years, depending on cable longevity and usage. Frequent plugging and unplugging, exposure to wear and tear, or visible damage can reduce their lifespan. Regularly inspecting for signs of damage helps determine if replacement is necessary sooner. Don’t wait until cables fail; proactive replacement ensures peak performance and safety, especially if you notice any connectivity issues or physical damage.

Are There Safety Concerns With Homemade or DIY Cables?

Yes, there are safety concerns with homemade or DIY cables. DIY hazards often include improper cable insulation, which can lead to shorts or electrical shocks. If you don’t use proper insulation materials or wiring techniques, it increases the risk of fire or damage to your equipment. Always guarantee your cables meet safety standards, and consider consulting a professional if you’re unsure about your DIY cable’s safety or insulation quality.

Can Electromagnetic Interference Affect Parallel Cable Safety?

Electromagnetic interference (EMI) can affect parallel cable safety by disrupting signals and potentially causing data loss or equipment malfunctions. To reduce EMI’s impact, you should verify your cable has proper shielding, which protects against external electromagnetic fields. Using shielded cables limits interference, keeps your connections stable, and enhances safety by preventing electrical noise from causing hazards or damage to connected devices.

Conclusion

By following these parallel cable safety rules, you protect your equipment and yourself. Think of your cables like delicate arteries—if you ignore damage or mishandling, risks increase, much like neglecting health can cause bigger issues. Regular inspections and proper storage act as preventative medicine, keeping everything flowing smoothly. When you treat your cables with care, you’re not just avoiding accidents—you’re ensuring long-lasting performance and safety for all your tech connections.