To master won’t hold load issues on your calculator quickly, start by understanding common causes like exceeding load capacity or worn components. Then, check power sources, reset to factory settings, and update firmware for stability. Inspect and replace faulty parts, run diagnostic tests, and perform routine maintenance. Stay proactive with load management and seek professional help if issues persist. The more you explore these steps, the better you’ll become at troubleshooting effectively.

Key Takeaways

- Understand common causes like overload, wear, and calibration errors to identify why the calculator won’t hold load.

- Reset the device to factory settings and update firmware to resolve software-related load issues quickly.

- Regularly inspect and replace faulty sensors, connectors, and circuit components to maintain accurate load measurements.

- Perform diagnostic tests and calibration procedures to ensure hardware and software are functioning correctly.

- Follow preventative maintenance routines and seek professional help if load problems persist beyond basic troubleshooting.

Understanding the Common Causes of Won’t Hold Load Errors

Won’t hold load errors often stem from specific, identifiable issues within the system. The most common cause is exceeding the load capacity, which puts stress on internal components and leads to failure. When you push beyond the calculator’s designed limits, it can cause component failure, resulting in errors. Another key factor is wear and tear; over time, parts may degrade, weakening the system’s ability to handle loads properly. Additionally, improper calibration or misreading of input data might misrepresent the actual load, causing the calculator to malfunction. Understanding these causes helps you identify the root problem quickly. Keep in mind, preventing these issues involves respecting load capacity limits and ensuring your components are in good condition. Proper system maintenance ensures longevity and reliable performance. Recognizing these common issues is the first step to troubleshooting effectively.

Preparing Your Calculator for Troubleshooting

Before you start troubleshooting, it’s vital to set up your calculator to guarantee precise outcomes and prevent additional problems. Begin by reviewing the user manual to understand the recommended calibration techniques specific to your model. Proper calibration ensures that measurements are accurate and consistent during troubleshooting. Check that all settings are correctly configured and reset any custom parameters if needed. Clean the device’s contacts and buttons to prevent any interference. Make sure the calculator is on a stable surface and free from dust or debris. Familiarizing yourself with the calibration procedures outlined in the manual helps you identify potential issues early. Additionally, understanding the best practices for maintenance can help maintain accuracy over time. Preparing your calculator this way minimizes errors and streamlines the troubleshooting process, setting a solid foundation for effective problem resolution.

Checking Power Sources and Battery Health

Have you checked whether your calculator’s power sources are functioning properly? Ensuring good battery longevity is key to maintaining reliable power stability. Start by inspecting the batteries for any corrosion or leakage, and replace them if they appear worn or damaged. If your calculator uses rechargeable batteries, test their charge levels and consider recharging or swapping them out. Low or inconsistent power can cause load issues, so a fresh, fully charged battery helps eliminate this as a factor. Also, verify that the power connections are secure and free of debris. Regularly checking your power sources and maintaining healthy batteries prevent unexpected shutdowns or performance drops, keeping your calculator running smoothly during critical calculations. Additionally, understanding Affairs – Cheating Husband Secrets can shed light on how emotional or environmental factors might subtly impact device performance over time if neglected.

Resetting Your Calculator to Factory Settings

To reset your calculator to factory settings, start by locating the reset button, usually found on the back or inside the battery compartment. Power off the device before pressing the button, then confirm the reset process as prompted. This quick step can often resolve persistent load issues and restore your calculator’s peak performance. Additionally, ensure your device’s firmware is up to date to prevent future problems related to fraud detection software.

Locate Reset Button

Locating the reset button on your calculator is the first step to restoring it to factory settings. Usually, it’s a small hole labeled “Reset” on the back or underside. Use a paperclip or a similar tool to press and hold the button for a few seconds. Before resetting, consider performing a battery replacement if your device’s display is flickering or showing errors—this can improve overall performance. Resetting also helps with display calibration issues, ensuring measurements are accurate. Once you’ve pressed the reset button, your calculator will reboot, returning to factory defaults. This process clears custom settings, including any display adjustments or calibration errors. After resetting, you may need to re-enter some preferences, but it’s the quickest way to troubleshoot load issues and restore proper functionality. Additionally, understanding digital literacy can help you better navigate and maintain your calculator’s features over time.

Power Off Device

Before resetting your calculator to factory settings, you should power off the device completely. Powering off ensures that no background processes interfere with the reset process. To do this, press and hold the power button until the screen goes dark. This simple step is a vital troubleshooting step, preventing potential errors during the reset. If your calculator has a separate reset button, make sure to use it only after powering off. Powering off the device also helps conserve battery life and prevents accidental input. Once your calculator is fully off, you can proceed with the reset process confidently, knowing the device is in a proper state. This step is indispensable in troubleshooting won’t hold load issues and restoring your calculator’s peak performance. Additionally, understanding angel numbers can offer spiritual guidance and reassurance during technical challenges.

Confirm Reset Process

Once you’ve initiated the reset, it is essential to confirm that the process is correctly underway. Check your calculator’s user interface for confirmation prompts or progress indicators. To guarantee proper reset, verify that all calibration techniques are reset to factory defaults, which can resolve load issues. Use the following table to identify signs of a successful reset:

| Indicator | What to Look For |

|---|---|

| Screen Display | Returns to factory default screen |

| Calibration | Reverts to original settings |

| User Interface | No residual data or custom settings |

| Load Function | Restores proper load handling |

If these signs appear, your reset was successful. If not, repeat the process or consult your device’s manual. Confirming the reset guarantees your calculator is ready for accurate load calculations. Additionally, reviewing the device’s home decor features can ensure your workspace is optimized for efficiency and comfort.

Updating Firmware and Software for Optimal Performance

Updating your firmware and software is essential for ensuring your load calculator performs at its best. Firmware updates fix bugs, improve stability, and add new features, while software optimization enhances accuracy and responsiveness. To start, visit the manufacturer’s website and download the latest firmware and software versions. Follow the provided instructions carefully—often involving connecting your device to a computer or using a dedicated update tool. Don’t skip this step, as outdated firmware can lead to incorrect load calculations or system crashes. Regular updates ensure compatibility with other tools and keep your calculator running smoothly. After installing updates, restart your device and verify that the new firmware and software are functioning correctly. Staying current maximizes performance and minimizes potential issues during use. Additionally, vetted resources can offer guidance and support if you encounter problems during the update process.

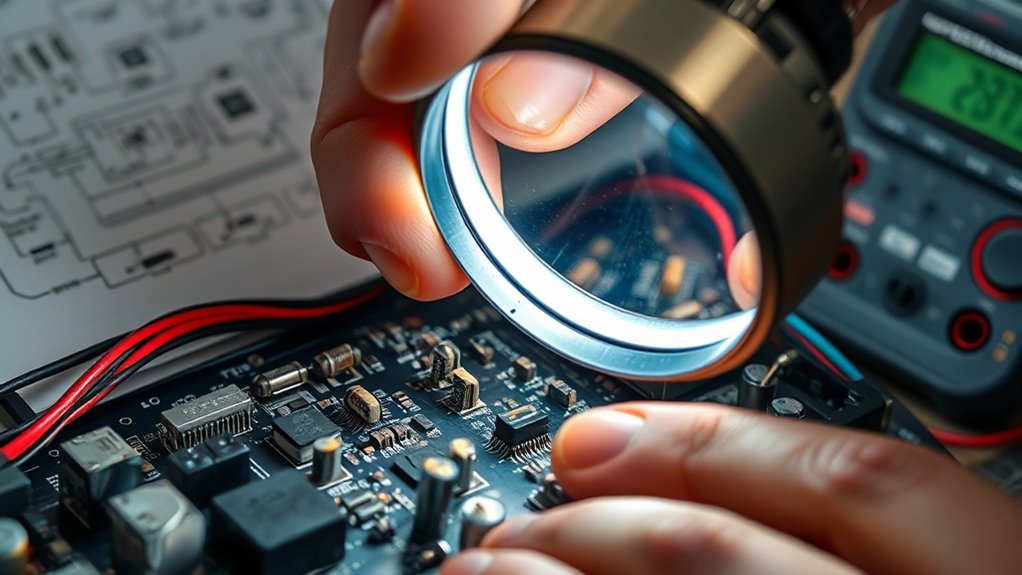

Inspecting and Replacing Faulty Components

If you notice inconsistent load readings or the calculator isn’t responding properly, faulty components might be the cause. Start by inspecting each part against its component specifications, ensuring they match manufacturer standards. Use calibration techniques to verify accuracy, focusing on sensors and connectors that could drift over time. Replace any damaged or outdated components with new ones that meet the original specifications to restore proper function. Pay close attention to connections and solder joints, as these can cause intermittent issues. Here’s a quick guide:

| Faulty Component | Symptoms | Action |

|---|---|---|

| Sensor | Erratic load readings | Calibrate or replace |

| Connector | Loose or corroded connections | Tighten or replace |

| Circuit Board | Physical damage or burns | Replace with matching specs |

Ensuring each part meets proper calibration techniques and specifications guarantees reliable, accurate results. Additionally, regularly inspecting electronic connections can help prevent unexpected failures and maintain optimal performance.

Running Diagnostic Tests to Identify Hardware Issues

To accurately identify hardware issues in the load calculator, you need to run targeted diagnostic tests. Begin with hardware diagnostics tools to scan for faulty components such as sensors or internal circuits that may cause load errors. Don’t forget to check the battery calibration; an improperly calibrated battery can lead to inaccurate load readings. Performing a battery calibration ensures the device’s power measurements are precise, helping rule out power-related issues. Use built-in diagnostic features or external software to perform these tests systematically. Focus on identifying inconsistencies or failures that could hinder proper load calculations. Once you pinpoint the problematic hardware or calibration issues, you can plan targeted repairs or replacements, effectively resolving the won’t hold load problem. Incorporating GMC tuning techniques can also optimize the overall performance of your diagnostic equipment for more accurate results.

Implementing Preventative Maintenance and Care Tips

To keep your load issues under control, you need to adopt regular inspection routines to catch problems early. Proper lubrication practices reduce wear and extend equipment life, while effective load management strategies prevent overloading. Implementing these care tips consistently helps maintain peak performance and avoids costly breakdowns.

Regular Inspection Routines

Regular inspection routines are essential for maintaining your load-bearing equipment and preventing unexpected failures. You should regularly check for signs of wear, damage, or misalignment, guaranteeing everything operates smoothly. Digital calibration tools can help you verify the accuracy of load measurements, catching issues early. Proper user training is vital so you and your team know what to look for during inspections and how to perform basic troubleshooting. Establish a routine schedule, documenting each inspection to track changes over time. This proactive approach helps identify problems before they escalate, saving you time and money. By integrating digital calibration and training into your routine, you guarantee your equipment remains reliable and safe, reducing the risk of load failures and improving overall performance.

Proper Lubrication Practices

Proper lubrication is a essential component of preventative maintenance that keeps load-bearing equipment operating smoothly and extends its lifespan. Using effective lubrication techniques ensures moving parts function efficiently and reduces wear and tear. To achieve this, you should follow a consistent maintenance schedule, applying the right type and amount of lubricant at recommended intervals. Regularly inspecting lubrication points helps prevent issues caused by over-lubrication or under-lubrication. Keep track of lubrication activities to maintain peak performance and avoid unexpected breakdowns. Proper lubrication not only minimizes friction but also protects against corrosion. By incorporating these practices into your routine, you safeguard your equipment’s reliability, reduce downtime, and maximize its operational life.

Load Management Strategies

Implementing effective load management strategies is crucial for preventing equipment failures and extending your machinery’s lifespan. Focus on load balancing to distribute work evenly across components, reducing stress on any single part. Proper resource allocation ensures each machine operates within its capacity, avoiding overloads that cause breakdowns. Regularly monitor load levels and adjust workloads proactively to prevent unexpected failures. Incorporate preventative maintenance routines that address wear and tear before issues escalate. By managing loads efficiently, you minimize strain, decrease downtime, and improve overall performance. Consistent assessment of load distribution and resource use helps you identify potential problems early. Ultimately, these strategies keep your equipment running smoothly, save costs, and extend its operational life.

When to Seek Professional Repair Assistance

Knowing when to call in a professional can save you time and prevent further damage. If troubleshooting your load issues involves complex calibration techniques or if user manual tips no longer resolve the problem, it’s time to seek expert help. Consider these signs:

When calibration and manual tips fail, consult a professional to prevent damage and ensure safety.

- The calculator consistently provides inaccurate load readings despite recalibration attempts.

- You suspect a hardware malfunction or internal component damage.

- Your efforts to follow calibration techniques or user manual tips don’t improve accuracy.

If these issues persist, professionals can diagnose and fix underlying problems safely. They have specialized tools and expertise beyond basic troubleshooting. Ignoring persistent issues may lead to more costly repairs or compromised safety. Don’t hesitate to consult a repair technician when your efforts no longer yield reliable results. Their assistance ensures accurate load management and peace of mind.

Frequently Asked Questions

Can Software Updates Cause Won’T Hold Load Issues?

Yes, software updates can cause won’t hold load issues. Sometimes, updates introduce software glitches that disrupt how your system manages loads, or they may conflict with existing hardware, leading to hardware malfunctions. These problems can affect your system’s stability, causing it to fail under pressure. To fix this, you might need to roll back updates or seek professional support to guarantee your software and hardware work seamlessly together.

How Do Environmental Conditions Affect Calculator Performance?

Don’t let environmental conditions ruin your calculations. Humidity interference can cause moisture buildup, skewing your data, while temperature fluctuations may affect the calculator’s internal components, leading to inaccuracies. You might think your device is reliable, but extreme weather can silently undermine your results. By keeping your calculator in a controlled environment, you guarantee consistent performance and accurate load assessments every time. Protect it, and trust your calculations.

Are There Specific Brands More Prone to These Problems?

Some brands tend to be more prone to load-holding issues due to varying model reliability. You’ll find that certain brands with a reputation for durability generally perform better, but model variations can influence reliability. Always check reviews for specific models and consider brand reputation before purchasing. By focusing on trusted brands known for consistent quality, you can minimize the risk of encountering load-holding problems and guarantee more reliable performance.

What’s the Typical Lifespan of Calculator Components?

Think of your calculator like a well-worn road—its lifespan depends on how often you use it. Typically, components last 3-5 years, but battery degradation and component wear can shorten that. Regularly replacing batteries and handling devices gently can extend its life. Keep an eye on signs of wear, and you’ll keep your calculator running smoothly, turning your calculations into a smooth ride rather than a bumpy journey.

How Can I Backup Data Before Resetting the Device?

Before resetting your device, you should perform a data backup to prevent losing important information. Connect your calculator to a computer or use any available backup feature to save your data. Follow the reset procedures carefully, ensuring all critical data is securely stored elsewhere. This way, you won’t lose valuable information, and you can restore your data easily after completing the reset. Always double-check that your backup is complete before proceeding.

Conclusion

So, now that you’ve mastered the art of troubleshooting won’t hold load errors, you’re basically a calculator whisperer. Who knew a few resets and checks could turn you into a tech genius? Just remember, if all else fails, professional help is just a call away—because even the smartest calculators sometimes need a doctor. Keep those batteries fresh, and your calculator will stay happy, and you’ll stay slightly less frustrated. Happy calculating!