To master altitude jets and tuning in a weekend, start by gathering the right tools and replacement jets suited for your engine. Learn to recognize signs that indicate needs for adjustment, like sluggish response or black smoke. Carefully remove, clean, and inspect your jets, then make precise adjustments to optimize performance at different altitudes. Test and fine-tune your engine, and follow preventative tips to keep everything running smoothly. Keep going, and you’ll unleash expert control over your jet tuning in no time.

Key Takeaways

- Gather all necessary tools, replacement jets, and safety gear before starting the maintenance process.

- Learn to identify signs of improper jet settings, such as engine hesitation or black smoke, for timely adjustments.

- Follow step-by-step procedures to carefully remove, inspect, clean, and replace jets safely and correctly.

- Make gradual, precise adjustments to the fuel mixture and needle position, testing engine response after each change.

- Keep detailed records of settings and maintenance steps to ensure consistent performance and easier troubleshooting.

Gathering the Necessary Tools and Supplies

Before you begin tuning your Altitude Jets, acquiring all the necessary tools and supplies is vital. You’ll need a basic set of screwdrivers, a clean workspace, and replacement jets, focusing on jet sizes suited for your engine. Having the correct tools guarantees you can easily access and adjust the jet screws without damaging components. Keep a small container to hold removed parts, and make sure to have a reliable fuel mixture that matches your engine’s requirements. Properly sized jet replacements are essential for fine-tuning performance at different altitudes. Additionally, a flashlight or magnifying glass can help you see small parts clearly. Preparing these supplies beforehand streamlines the process, prevents delays, and sets you up for precise adjustments during your tuning session. Understanding jet sizes is crucial for selecting the right replacements for optimal engine performance.

Understanding When and Why You Need to Adjust Altitude Jets

You’ll know it’s time to adjust your altitude jets when you notice your engine running too rich or too lean at certain elevations. Recognizing these conditions helps you maintain ideal performance and avoid potential damage. Knowing when to make these adjustments ensures your jetting stays in sync with changing altitude and engine needs. Proper tuning can also prevent issues related to air-fuel mixture, which is vital for efficient engine operation at various heights.

Recognizing Altitude Effects

Recognizing when to adjust your altitude jets is essential for maintaining ideal engine performance as you change elevations. Weather variability can influence engine behavior, causing fluctuations in power and fuel efficiency. If you notice your engine running rough, losing power, or inconsistent throttle response at higher altitudes, it’s a sign you need to reassess your jets. Changes in temperature, humidity, and pressure directly affect how your engine breathes, making adjustments necessary to keep it running smoothly. Additionally, tuning your Kia Tuning components appropriately can help optimize your vehicle’s response to altitude changes. By paying close attention to these signs, you can determine whether altitude jet tuning is required. Correctly recognizing these altitude effects ensures your engine performs at its best, prevents potential issues, and keeps your flying experience safe and efficient.

Identifying Rich/Lean Conditions

When altitude changes affect your engine’s performance, understanding whether it’s running rich or lean helps determine if jet adjustments are needed. Signs of a rich condition include sluggish acceleration, black smoke from the exhaust, or fouled spark plugs. Conversely, a lean condition may cause hesitation, overheating, or engine misfires. Proper carburetor calibration is essential to identify these issues accurately. Using the right jet size selection ensures your engine maintains ideal fuel-to-air ratio at different altitudes. If your engine runs too rich, you might need to install smaller jets; if too lean, larger jets are necessary. Recognizing these symptoms allows you to fine-tune your altitude jets effectively, ensuring smooth performance and preventing engine damage during altitude changes. Additionally, creating a cozy farmhouse bedroom can help you relax and enjoy the process of tuning your engine in comfort.

Timing Jet Adjustments

Adjusting altitude jets becomes necessary when your engine’s performance shifts unexpectedly as you change elevation, impacting fuel mixture and power output. Proper carburetor calibration depends on accurate jet size selection, which guarantees optimal engine response. Timing jet adjustments are vital when you notice inconsistent throttle response, rough running, or decreased power at different altitudes. By fine-tuning the jet size, you can maintain a proper air-fuel mixture, preventing lean or rich conditions that hinder performance. Keep an eye on engine behavior during altitude changes and be prepared to adjust your jets accordingly. These adjustments help preserve fuel efficiency and engine longevity, making sure your carburetor remains properly calibrated for varying conditions. Regular tuning ensures your engine runs smoothly no matter your elevation.

Identifying Symptoms of Improper Jet Settings

If your altitude jet settings are off, your engine may not perform as expected, which can lead to noticeable issues during operation. Poor jet performance often results in rough idling, sputtering, or hesitation during acceleration. You might notice a loss of power or inconsistent throttle response, especially at higher altitudes. During carburetor tuning, these symptoms indicate that the jets aren’t supplying the right amount of fuel. Another sign is excessive fouling or black smoke from the exhaust, showing an overly rich mixture. Conversely, if the engine runs lean, it may backfire or overheat. Recognizing these symptoms helps you identify improperly set altitude jets early, ensuring you can adjust them before more serious damage occurs. Proper jet tuning restores ideal engine performance and smooth operation. Additionally, understanding the tuning process can help you fine-tune your jets more effectively for optimal performance.

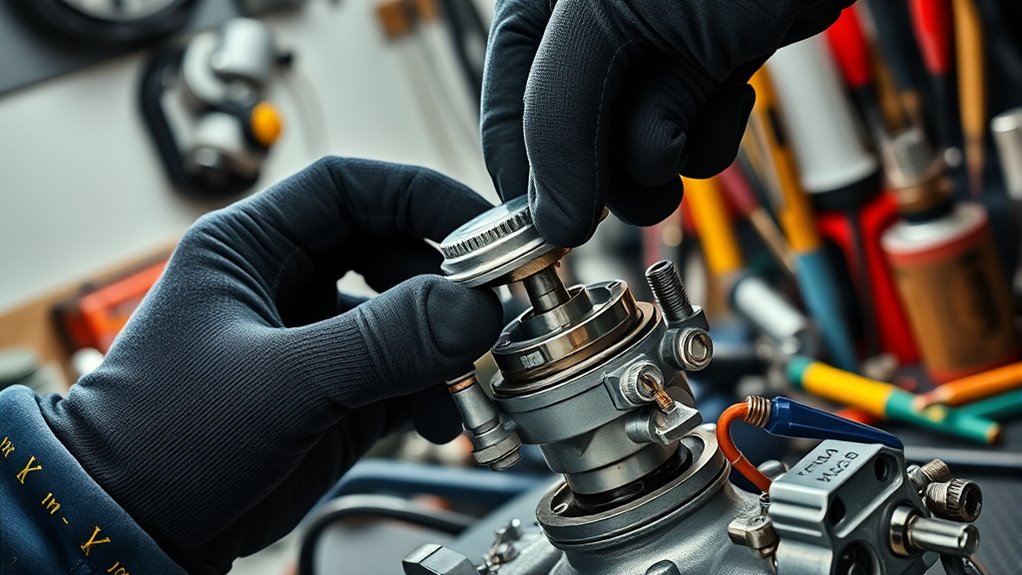

Removing and Inspecting Your Altitude Jets

To properly remove and inspect your altitude jets, start by making sure the engine is cool and disconnecting the spark plug wire for safety. This prevents accidental starts during the process. Next, locate the jets in your carburetor and carefully perform jet removal using the appropriate tools. Follow these key inspection techniques:

- Check for clogs, debris, or corrosion that may hinder airflow.

- Look for signs of damage, such as cracks or excessive wear.

- Ensure the jets are free of dirt, and the openings are clear.

- Pay attention to color accuracy to ensure the jets are functioning properly with the fuel mixture.

Careful inspection helps you identify any issues that could affect engine performance. Handle the jets gently to avoid damage. Regular jet removal and inspection techniques keep your tuning precise and your engine running smoothly at high altitudes.

Cleaning and Replacing Jets Safely

Before you start cleaning or replacing your jets, always prioritize safety by disconnecting the power and wearing protective gear. Follow proper replacement techniques to guarantee the jets are installed correctly and avoid damage. Taking these steps helps keep your maintenance safe and effective. Additionally, understanding the second trimester can help you plan your maintenance schedule around your pregnancy milestones.

Safety Precautions First

Cleaning and replacing jets require careful attention to safety to prevent accidents or damage. First, always wear safety glasses and gloves to protect your eyes and skin from debris or fuel spills. Confirm your workspace is well-ventilated to avoid inhaling fumes. Before starting, double-check that your tools are in good condition and suitable for the job to maintain tool safety. Additionally, ensure that you are aware of proper water safety procedures if working near any water sources to prevent slips or falls. Remember to:

- Disconnect the power supply or fuel line to eliminate the risk of leaks or sparks

- Use the correct tools to avoid slips or damage to components

- Keep your workspace organized to prevent accidents

Prioritizing safety precautions helps you avoid injury and ensures your maintenance session is smooth and effective.

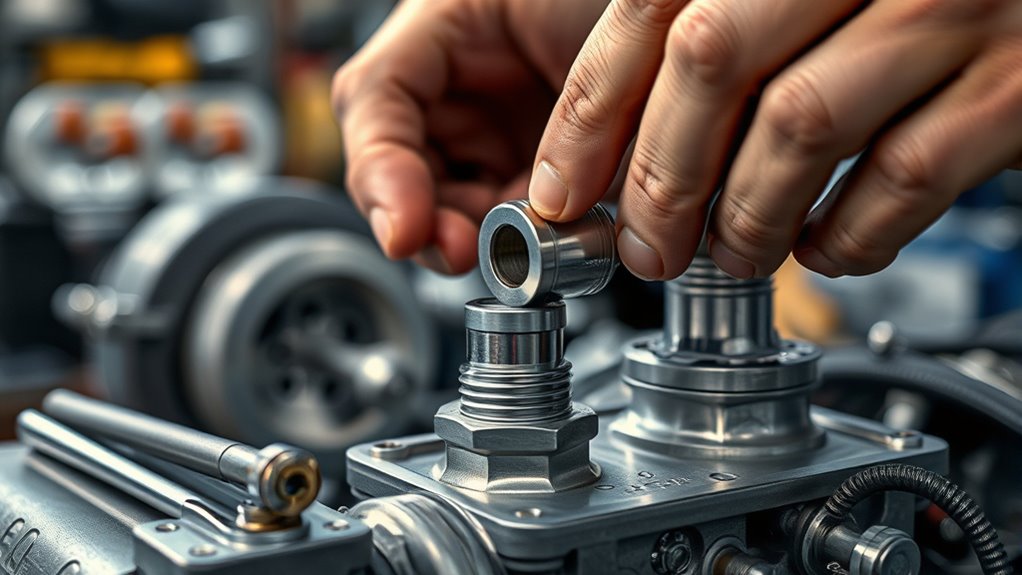

Proper Replacement Techniques

When cleaning and replacing jets, practicing proper techniques is vital to guarantee safety and prevent damage. Always handle jets carefully to avoid damaging the jet material, which varies depending on the engine type. Pay attention to replacement timing; replacing jets too early or late can affect performance. Before removal, turn off the engine and make certain it’s cooled down. Use the correct tools for extraction and installation, and avoid forcing components. Keep track of jet sizes and specifications to match manufacturer recommendations. Additionally, understanding the material composition of jets can help determine the appropriate maintenance approach and prolong their lifespan.

Making Precise Adjustments for Optimal Performance

Achieving ideal performance on your Altitude Jets requires making precise adjustments that fine-tune the engine’s settings. Focus first on the fuel mixture, ensuring it’s neither too rich nor too lean, which impacts power and efficiency. Next, carefully adjust needle positioning to control fuel flow and throttle response. To make effective adjustments:

- Fine-tune the fuel mixture by turning the mixture screw gradually.

- Adjust the needle position to optimize power delivery at different throttle levels.

- Test after each change, listening for smooth acceleration and stable idling.

- Remember that performance factors such as external conditions can also influence tuning outcomes.

Precision is key; small changes yield significant results. Keep track of adjustments to find the perfect balance, ensuring your engine runs smoothly and efficiently at altitude. This process sharpens your tuning skills and maximizes performance.

Testing and Fine-Tuning After Maintenance

After completing maintenance on your Altitude Jets, it’s vital to methodically test and fine-tune the engine to guarantee peak performance. Begin with a thorough carburetor inspection to ensure no blockages or leaks. Adjust the fuel mixture for ideal combustion, balancing richness and leaness based on engine response. Perform a series of test runs, observing RPM stability and throttle response. Use the table below to guide your fine-tuning process:

| Step | Action | Result |

|---|---|---|

| Initial Test | Run engine at idle, check for smoothness | Smooth idle, no stalling |

| Fuel Mixture Adjustment | Slightly lean or enrich mixture | Improved throttle response |

| Final Inspection | Recheck carburetor and fuel lines | No leaks, proper flow |

Repeat testing until the engine runs smoothly across all parameters.

Tips for Preventative Maintenance and Troubleshooting

Regular preventative maintenance is essential to keep your Altitude Jets running reliably and to catch issues before they escalate. Consistent checks help you spot problems with fuel mixture, ignition timing, and overall system health early on. To troubleshoot effectively, focus on:

- Ensuring the fuel mixture is properly balanced for altitude adjustments

- Verifying ignition timing is correctly set for smooth operation

- Inspecting jets and hoses for clogs, leaks, or wear

Documenting Your Settings and Maintenance Schedule

Keeping detailed records of your altitude jet settings and maintenance activities is key to maintaining consistent performance. By tracking performance over time, you can identify patterns and spot when adjustments are needed. Document every change you make to your jets, including the date, settings, and the results you observe. This helps you understand how different tuning adjustments impact your engine’s behavior. Regularly updating your maintenance schedule ensures you don’t overlook routine tasks, reducing the risk of unexpected issues. Organized documentation allows you to compare past and current settings easily, making troubleshooting more efficient. Ultimately, diligent record-keeping empowers you to fine-tune your altitude jets effectively and sustain excellent engine performance weekend after weekend.

Frequently Asked Questions

How Often Should I Check My Altitude Jets for Optimal Performance?

You should check your altitude jets for essential performance at least once a month. Regular jet cleaning guarantees they stay free of debris, and adjusting the jets when you notice changes in engine performance is vital. Keep an eye on your engine’s responsiveness and fuel efficiency, and don’t delay jet cleaning or adjustment frequency if you notice issues. Consistent maintenance helps maintain smooth operation and prevents costly repairs down the line.

Can Improper Jet Tuning Cause Engine Damage?

Improper jet tuning can indeed cause engine damage. If you ignore jet corrosion or misadjust the fuel mixture, you risk lean or rich conditions that strain your engine. These issues can lead to overheating, fouled spark plugs, or even engine failure. Always check your jets regularly, especially in harsh conditions, to prevent damaging your engine. Proper tuning isn’t just performance—it’s essential for your engine’s longevity.

What Tools Are Essential for Adjusting Altitude Jets Precisely?

You’ll need a set of precise screwdrivers and a tachometer for carburetor calibration and jet size selection. A vacuum gauge helps guarantee accurate adjustments, while a jet wrench makes removing and installing jets easier. Use a calibrated fuel pressure gauge to maintain consistent fuel delivery. These tools allow you to fine-tune altitude jets effectively, ensuring peak engine performance and preventing damage caused by improper jet tuning.

How Do Weather Changes Affect Altitude Jet Settings?

Weather changes, especially temperature and pressure shifts, directly impact your fuel mixture and engine response. Cooler, denser air requires richer mixture adjustments, while warmer, less dense air calls for leaner settings. You need to tweak your altitude jet accordingly to maintain ideal engine performance. Monitoring weather conditions helps you fine-tune the jet, ensuring smooth operation and preventing engine issues caused by inconsistent altitude or temperature variations.

Are There Safety Precautions to Consider During Jet Maintenance?

Think of jet maintenance as steering a storm—you need safety gear and hazard awareness to stay afloat. Always wear protective gloves, goggles, and a mask to shield yourself from fumes and debris. Turn off power sources before working on jets, and guarantee proper ventilation. Keep your workspace organized to avoid accidents. Staying cautious and prepared helps prevent injuries, making your maintenance safe and effective as you fine-tune your altitude jets.

Conclusion

Mastering altitude jets in a weekend might seem intimidating, but here you are—ready to conquer it all. Ironically, once you understand the basics, the most complex part is just remembering to document your settings. So, go ahead—tune with confidence, knowing that your meticulous efforts will keep your engine running smoothly, even if the weather changes. After all, who knew that a tiny jet could challenge your skills and your weekend?