To keep your inverter generator running smoothly, follow the manufacturer’s maintenance schedule closely. Track your operating hours to determine when to change oil, replace filters, and check the spark plug. Regularly inspect the air filter and monitor battery health. Calculate fuel and load capacities to prevent overloads and ensure efficiency. Staying organized with maintenance records helps catch issues early. Continue exploring to discover simple calculations that keep your generator reliable and quiet.

Key Takeaways

- Follow the manufacturer’s recommended maintenance schedule for oil changes, filter replacements, and inspections to ensure optimal performance.

- Regularly check and monitor oil quality and viscosity to determine when oil changes are necessary, extending engine life.

- Replace fuel and air filters at specified intervals and watch for signs of clogging, such as reduced power or difficulty starting.

- Track battery health, load, and runtime to prevent overloads and ensure reliable operation; keep detailed maintenance logs.

- Maintain spark plugs and air filters proactively, and keep organized records to support troubleshooting and prolong generator lifespan.

Understanding the Manufacturer’s Maintenance Timeline

Understanding the manufacturer’s maintenance timeline is essential for keeping your inverter generator running smoothly. Regular maintenance helps optimize fuel efficiency, so your generator uses less fuel and saves you money over time. It also plays a key role in noise reduction, ensuring your generator operates quietly and doesn’t disturb your surroundings. Manufacturers provide specific intervals for tasks like inspecting filters, cleaning components, and replacing worn parts. Sticking to these schedules prevents unexpected breakdowns and maintains peak performance. By understanding and following the recommended timeline, you’ll keep your inverter generator reliable, efficient, and quiet. Remember, neglecting maintenance can lead to decreased fuel efficiency and increased noise levels, making your generator less effective and more disruptive. Stay proactive, consult your manual, and keep your generator in top shape. Water filtration systems can serve as a helpful analogy for understanding the importance of scheduled maintenance in keeping your equipment optimal.

Calculating Oil Change Intervals Based on Operating Hours

Knowing when to change your inverter generator’s oil depends on operating hours and oil condition. You should track your hours and watch for signs of oil degradation, like darkening or thinning. By understanding these benchmarks and indicators, you can set accurate oil change intervals to keep your generator running smoothly. Regularly inspecting the oil quality can help prevent engine damage and extend the lifespan of your generator.

Operating Hour Benchmarks

How often should you change the oil in your inverter generator? Typically, every 100 hours of operation, but this can vary based on usage conditions. Tracking your operating hours helps guarantee ideal fuel efficiency and keeps noise levels manageable. If you use your generator frequently or in harsh environments, consider shortening the interval. Conversely, if it runs infrequently, you might extend the time between oil changes, but don’t skip regular checks. Setting clear hour benchmarks keeps your generator running smoothly and prevents engine wear. Regular oil changes based on these benchmarks maintain peak performance, improve fuel efficiency, and keep noise levels low. Use a timer or keep a log to monitor hours accurately—this simple step saves you time and money in the long run. Additionally, understanding AI in Education can inform smarter maintenance scheduling through data analysis and automation tools.

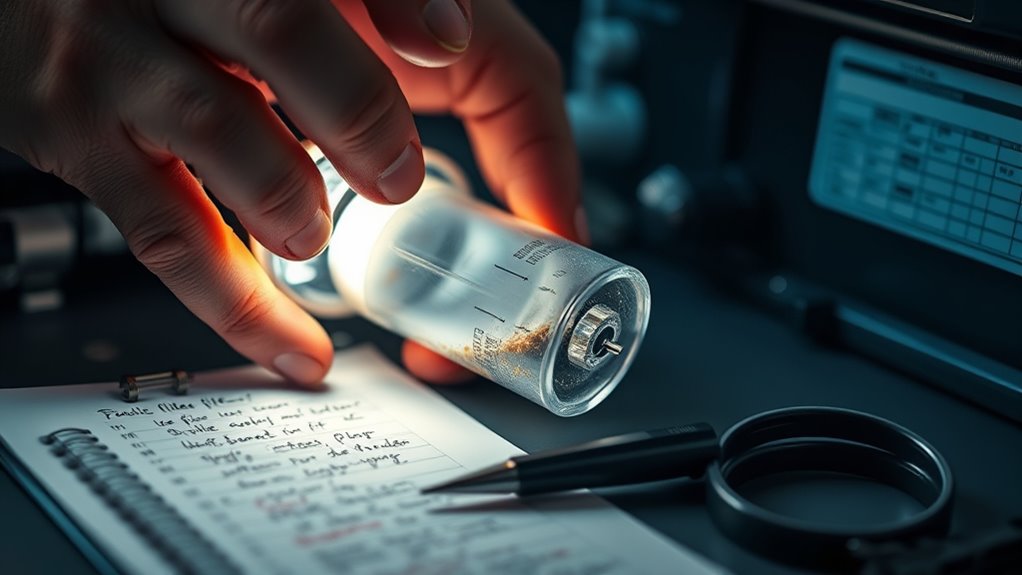

Oil Degradation Indicators

Oil degradation indicators provide valuable clues about when to change your inverter generator’s oil, especially since oil quality diminishes over time as it breaks down and accumulates contaminants. One key indicator is changes in oil viscosity; as oil degrades, it often becomes thinner or thicker, signaling it may no longer lubricate properly. Additionally, increased oil contamination from dirt, fuel, or moisture can reduce oil’s effectiveness and accelerate wear. Regularly inspecting the oil for these signs helps you determine if it’s time for an oil change, rather than relying solely on operating hours. Monitoring these indicators ensures your generator runs smoothly, maintains ideal performance, and prolongs engine life. Staying vigilant about oil viscosity and contamination levels is essential for a reliable maintenance schedule. Moreover, understanding AI security vulnerabilities in monitoring systems can help you implement more effective diagnostic tools for early detection of oil issues.

Estimating Fuel Filter Replacement Schedule

Your fuel filter’s lifespan depends on how often you use your generator and the quality of fuel you put in. Frequent use or dirty fuel can cause it to clog faster, leading to performance issues. Keep an eye out for signs like reduced power or engine stalls to determine if a replacement is needed.

Fuel Filter Lifespan

Determining the *key* timing for replacing your inverter generator’s fuel filter is *essential* to maintain *peak* performance. The fuel filter lifespan varies depending on usage and fuel quality but generally falls between 300 to 500 hours of operation. To avoid engine issues, it’s *vital* to monitor your generator’s operating hours and adhere to recommended replacement intervals. Regularly inspecting the filter for signs of clogging or debris can also help you catch problems early. If you notice decreased efficiency or trouble starting, it might be time to replace the filter sooner. Sticking to the manufacturer’s guidelines ensures your fuel filter functions effectively, preventing contaminants from reaching the engine and prolonging your generator’s lifespan. Proper scheduling keeps your inverter generator running smoothly and reliably. Additionally, understanding AI’s impact on business can help you stay ahead with innovative maintenance solutions and predictive analytics.

Usage Frequency Effects

The frequency with which you use your inverter generator directly impacts how often you’ll need to replace the fuel filter. If you operate it frequently, contaminants and debris can build up faster, reducing fuel efficiency and potentially causing the generator to work harder. This increased workload may also lead to more noise, making your generator louder and less smooth. Regular use without proper maintenance can cause clogging, which hampers fuel flow and decreases overall performance. By monitoring your usage, you can better estimate when to replace the fuel filter, ensuring ideal fuel efficiency and noise reduction. Less frequent use may extend the filter’s life, but proper maintenance is key to keeping your generator running smoothly and quietly over time.

Signs of Clogging

Clogging signs in your fuel filter often become noticeable through changes in your generator’s performance. You might experience reduced power, difficulty starting, or inconsistent running. These are clear airflow restrictions caused by debris or buildup blocking fuel flow. If your generator stalls unexpectedly or runs rough, it’s a strong indicator of clogging signs. You may also notice increased fuel consumption or difficulty maintaining a steady RPM. Regularly inspecting the fuel filter can help you catch these airflow restrictions early. When you observe persistent performance issues despite proper maintenance, it’s a time to contemplate replacing the fuel filter. Addressing clogging signs promptly ensures your generator runs smoothly and efficiently, preventing further damage and maintaining reliable operation during outages or essential tasks. Additionally, understanding industry trends can help inform your maintenance schedule and improve your overall troubleshooting approach.

Determining Spark Plug Replacement Timing

Knowing when to replace your inverter generator’s spark plug is essential for maintaining ideal performance. You should check the spark plug gap regularly, ensuring it matches the manufacturer’s specifications. An incorrect gap can disrupt ignition timing, causing inefficient combustion and reduced power. Typically, spark plugs need replacement after about 100-200 hours of operation, but this can vary based on usage and fuel quality. Inspect the spark plug for signs of wear, carbon buildup, or damage. If the electrode is worn down or the insulator is cracked, it’s time for a new one. Proper ignition timing depends on a clean, well-gapped spark plug; replacing it when necessary keeps your generator running smoothly and prevents potential misfires or starting issues. Additionally, using the correct headphone connection can ensure clear audio during maintenance or troubleshooting.

Monitoring and Calculating Air Filter Maintenance Needs

Monitoring your inverter generator’s air filter is essential for peak performance. A clean air intake ensures maximum filter efficiency, preventing dirt and debris from clogging the system. Regular inspection helps you identify when the filter is dirty or damaged, which can reduce airflow and strain the engine. To calculate maintenance needs, note the operating hours since the last filter change and compare them to the manufacturer’s recommended interval. Keep an eye on visible dirt, dust buildup, and pressure differences if your model has a pressure gauge. Cleaning or replacing the filter at appropriate intervals maintains proper air intake and keeps your generator running smoothly. Additionally, understanding HEPA filtration can help you choose the best filters for optimal air quality. Consistent monitoring saves you money and prevents unexpected breakdowns, making your maintenance routine more effective.

Assessing Battery Health and Replacement Calculations

Regularly evaluating your inverter generator’s battery health is essential to guarantee reliable startup and operation. You should monitor the battery’s voltage stability, which indicates its overall condition. A healthy battery maintains consistent voltage levels, ensuring your generator starts smoothly. Over time, batteries experience a natural decline in lifespan, so tracking voltage fluctuations helps identify when replacement is necessary. Use a multimeter to check the voltage; if it drops below the manufacturer’s recommended threshold, it’s time to contemplate a replacement. Calculating the remaining battery lifespan involves noting the number of charge cycles and performance trends. Additionally, keeping track of AI-driven solutions in maintenance practices can help optimize battery management. By staying proactive, you prevent unexpected failures and extend your generator’s reliability, saving you money and hassle in the long run. Regular assessments keep your inverter generator running smoothly when you need it most.

Calculating Load and Runtime for Optimal Performance

To guarantee your inverter generator operates efficiently, accurately calculating the load and runtime is essential. Knowing your power needs helps optimize power efficiency and noise reduction, making your generator run smoother. Begin by listing your essential devices and their wattage. Then, estimate total load and compare it to your generator’s capacity. Use this table to plan:

| Device | Wattage (W) |

|---|---|

| Laptop | 100 |

| Refrigerator | 200 |

| Lights | 50 |

| Total Load | 350 W |

Calculating runtime involves dividing your fuel capacity by the load. This ensures your generator runs efficiently, reducing unnecessary noise and maximizing power efficiency during operation.

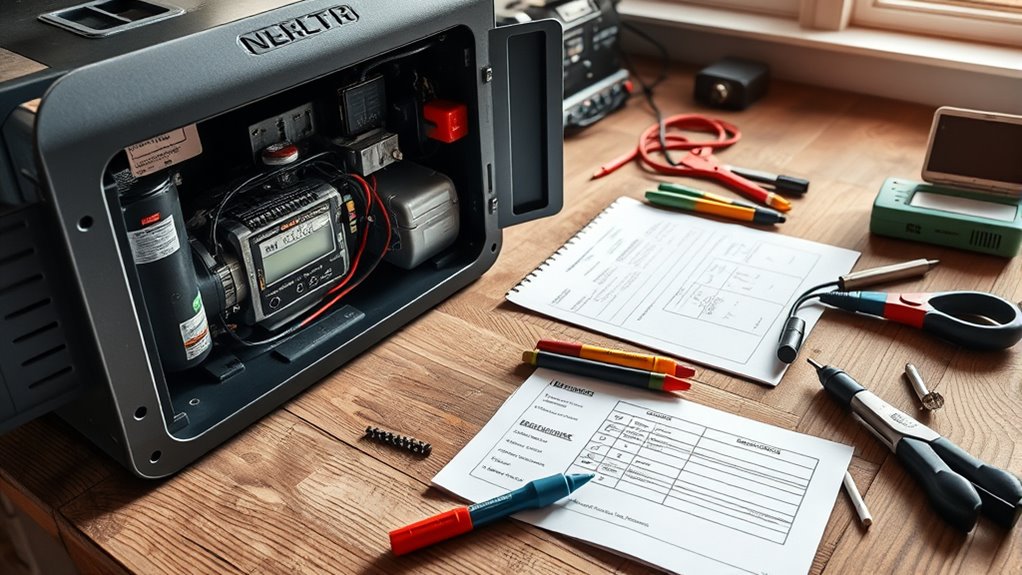

Tracking Maintenance Records for Longevity

Keeping detailed maintenance records for your inverter generator helps guarantee it stays in top condition and lasts longer. By tracking maintenance records, you create a clear history of repairs, part replacements, and routine checks, which is essential for effective longevity planning. You’ll know when to perform tasks like oil changes, filter replacements, and inspections, preventing unexpected breakdowns. Maintaining these records allows you to identify patterns that might signal upcoming issues, giving you a proactive approach. Consistent documentation also helps if you need warranty service or resale, proving proper maintenance. Staying organized with your records ensures you follow your maintenance schedule precisely, maximizing your generator’s lifespan and reliability. In the long run, good tracking saves you time, money, and hassle, keeping your inverter generator running smoothly for years.

Using Basic Math to Diagnose and Prevent Common Issues

By applying basic math skills, you can effectively diagnose and prevent common inverter generator issues before they become serious problems. For voltage regulation, track voltage output over time; if it consistently fluctuates outside the recommended range, your generator may need maintenance. Use simple calculations to compare voltage readings and identify irregularities early. For noise reduction, measure decibel levels at different loads; a sudden increase indicates potential mechanical or electrical issues. Calculating average noise levels helps determine if your generator operates smoothly or requires inspection. Regularly analyzing these measurements allows you to spot issues like voltage instability or excessive noise early, saving you from costly repairs and downtime. Basic math provides a practical way to keep your inverter generator running efficiently and reliably.

Frequently Asked Questions

How Often Should I Perform a Full Inverter Generator Tune-Up?

You should perform a full inverter generator tune-up every 6 to 12 months, depending on usage. During this, change the oil, inspect and replace the spark plug, and check overall performance. Regular oil changes keep the engine running smoothly, while a new spark plug ensures reliable starts. Keeping up with this schedule prevents breakdowns and prolongs your generator’s lifespan. Adjust frequency based on how often and intensively you use it.

Can I Extend Maintenance Intervals With Synthetic Oil?

You can stretch maintenance intervals with synthetic oil, but don’t push your luck. Synthetic benefits include better oil longevity and superior engine protection, which means fewer oil changes and extended periods between tune-ups. However, it’s wise to follow your generator’s manual and monitor oil levels regularly. Synthetic oil can help, but neglecting routine checks might still lead to issues; think of it as giving your generator a longer, smoother ride.

What Signs Indicate I Need to Replace My Fuel Filter Sooner?

You should replace your fuel filter sooner if you notice engine performance issues like rough idling, stalling, or decreased power. These signs indicate your fuel filter lifespan might be shorter than usual. Also, if you see debris or dirt in the filter during inspection, it’s a clear sign to change it. Regularly monitoring these symptoms helps maintain ideal engine performance and prevents potential damage caused by clogged filters.

How Do Temperature Changes Affect Maintenance Schedules?

You notice how the ambient temperature drops, and suddenly your inverter generator runs hotter. Temperature changes directly impact maintenance schedules, as colder weather can slow engine cooling, requiring more frequent oil or filter checks. Conversely, hot environments accelerate wear, prompting earlier inspections. Always monitor how ambient temperature affects your generator’s performance, so you can adjust your maintenance routine accordingly, ensuring peak cooling and longevity regardless of the climate.

Is There a Way to Track Maintenance Costs Over Time Effectively?

You can track maintenance costs effectively by using expense analysis tools like spreadsheets or dedicated apps. Record all costs related to parts, labor, and services over time, then review the data regularly. This helps you identify spending patterns, predict future expenses, and optimize your maintenance budget. Consistent cost tracking guarantees you stay within budget, avoid unexpected expenses, and maintain your inverter generator’s performance efficiently.

Conclusion

By following these simple calculations, you’ll keep your inverter generator running smoothly like a well-oiled machine. Staying on top of maintenance isn’t just about avoiding breakdowns; it’s about giving your power source the care it needs to serve you reliably. Remember, regular upkeep is the secret sauce to longevity. With these easy math tricks, you’ll turn maintenance from a chore into a breeze, ensuring your generator’s performance stays as steady as a heartbeat.