To keep your inverter generator electronics reliable, perform regular preventive maintenance by inspecting components for signs of wear, corrosion, or overheating. Use multimeters to test resistance, capacitance, and continuity, and replace faulty parts promptly. Update firmware when available to guarantee peak performance. Regularly scheduling these checks helps prevent failures and extends the system’s lifespan. Continue with these steps to learn how detailed testing and proactive upkeep can safeguard your investment effectively.

Key Takeaways

- Regularly inspect electronic components for signs of wear, corrosion, or overheating to prevent unexpected failures.

- Test resistors, capacitors, and connections with multimeters to ensure proper operation and identify potential faults early.

- Keep firmware updated by downloading the latest versions from the manufacturer and following proper installation procedures.

- Replace faulty components promptly, such as capacitors or resistors, to maintain inverter performance and prevent damage.

- Schedule routine maintenance checks to verify system stability, extend generator lifespan, and ensure electronics operate reliably.

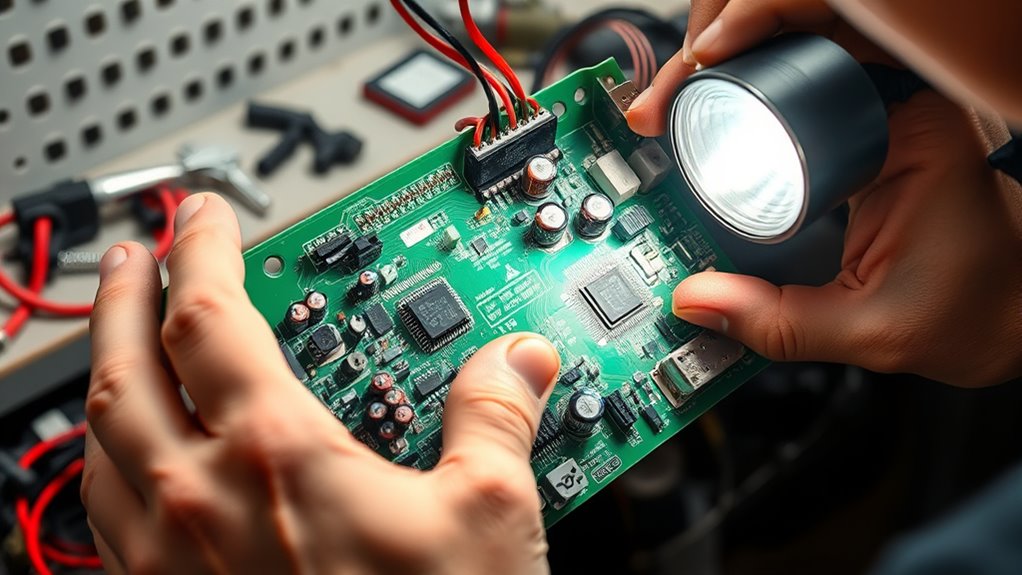

Regular preventive maintenance is essential to keep your inverter generator’s electronics running smoothly and reliably. A key part of this process involves systematic electronic component testing. Over time, components like capacitors, resistors, and transistors can degrade or develop faults that might not be immediately apparent but could cause performance issues or complete failures if left unchecked. By regularly testing these components, you can identify potential problems early, preventing costly repairs or replacements down the line. Use a multimeter or specialized testing tools to check for proper resistance, capacitance, and continuity. Pay close attention to any signs of wear, corrosion, or overheating, and replace faulty parts promptly to maintain ideal operation. This proactive approach ensures your generator’s electronics stay in top condition and reduces the risk of unexpected breakdowns during critical times.

In addition to physical testing, keeping your inverter generator’s firmware up to date is another essential aspect of preventive maintenance. Firmware updates often include bug fixes, security patches, and performance improvements that enhance the stability and efficiency of your generator’s electronic systems. Outdated firmware can lead to compatibility issues, reduced functionality, or even system errors that might be difficult to diagnose. Hence, it’s important to follow the firmware update procedures recommended by the manufacturer. Typically, this involves downloading the latest firmware version from the manufacturer’s website, preparing a USB drive or memory card, and following specific instructions for installation. Make sure your generator is connected to a stable power source during the update process to prevent interruptions. Some updates may require you to reset certain settings or perform calibration steps afterward, so read the instructions carefully. Regularly updating firmware not only keeps your electronics current but also guarantees they operate with the latest improvements, boosting your generator’s overall reliability. Additionally, understanding the importance of electronic component health can help you better maintain your system’s longevity and performance.

Implementing these maintenance routines might seem straightforward, but they play a significant role in extending your inverter generator’s lifespan. Electronic component testing helps you catch issues early, saving you from unexpected failures, while firmware updates keep your system running smoothly with the latest enhancements. Both practices require a bit of diligence and attention to detail but are well worth the effort. By dedicating time to these tasks at regular intervals, you’re effectively safeguarding your investment and making sure your generator is always ready when you need it most. Remember, consistent preventive maintenance is the best way to avoid costly repairs, minimize downtime, and keep your inverter generator operating at peak performance for years to come.

Frequently Asked Questions

How Often Should Inverter Generator Electronics Be Inspected?

You should inspect your inverter generator electronics every 6 to 12 months. During these inspections, perform electronic diagnostics to identify potential issues early. Check for loose connections, wear, or corrosion, and replace any faulty components promptly to prevent major failures. Regular inspections help guarantee peak performance, extend the lifespan of your generator, and avoid unexpected breakdowns, saving you time and money in the long run.

What Are Common Signs of Electronic Component Failure?

Think of your inverter generator’s electronics as a finely tuned orchestra. If you notice flickering displays, unusual noises, or difficulty starting, these are signs of electronic diagnostics revealing that some components are out of harmony. You might see warning lights or erratic performance, signaling it’s time for component replacement. Addressing these signs early prevents bigger issues, keeping your generator running smoothly and ensuring your electronics hit all the right notes.

Can I Perform Preventive Maintenance Myself?

Yes, you can perform preventive maintenance yourself if you follow DIY safety protocols and have basic electronic diagnostics skills. Start by inspecting the inverter generator for loose connections, dust buildup, or worn parts. Use appropriate tools and avoid working on live circuits. Regularly cleaning and checking for signs of wear help prevent failures. If you’re unsure, consult the manual or seek professional help to guarantee safety and accuracy.

What Special Tools Are Needed for Electronic Maintenance?

A stitch in time saves nine, so having the right tools is essential. For electronic maintenance, you’ll need diagnostic tools like multimeters and circuit testers to identify issues accurately. These tools help you measure voltage, check continuity, and troubleshoot circuits safely. Investing in quality equipment guarantees you can perform preventive maintenance effectively, preventing costly repairs down the line. Remember, proper tools make all the difference in keeping your inverter generator running smoothly.

How Does Temperature Affect Inverter Generator Electronics?

Temperature critically impacts inverter generator electronics by affecting thermal management and circuit protection. When temperatures rise, components can overheat, risking damage or failure; proper thermal management helps dissipate heat efficiently. Conversely, low temperatures can cause brittle circuits or sluggish performance. You should monitor operating temperatures closely and guarantee cooling systems are functioning well. Maintaining ideal temperatures preserves circuit protection and keeps your inverter electronics running smoothly and reliably.

Conclusion

By regularly inspecting and caring for your inverter generator’s electronics, you’re keeping its heart healthy and ready to beat when you need it most. Picture the smooth hum of a well-maintained engine, sparks flying only in your imagination, not from neglect. With each check, you’re building a fortress of reliability, ensuring your power source stands strong through storms and blackouts. Stay vigilant, and your generator will serve you quietly and confidently for years to come.