If your generator runs rough under load, start by inspecting the ignition system. Check the spark plug for wear or damage and ensure the ignition coil delivers a strong spark. Also, examine the wiring connections for looseness or corrosion. For fuel issues, inspect the fuel filter and carburetor for clogs or dirt. Properly diagnosing these components can often solve the problem, and more tips can help you pinpoint the root cause effectively.

Key Takeaways

- Inspect spark plugs for wear, damage, or fouling, and replace if necessary to ensure strong sparks under load.

- Test ignition coil output to confirm it produces a consistent, strong spark during load conditions.

- Check and tighten all wiring connections to prevent loose or corroded contacts affecting ignition performance.

- Examine fuel lines and filters for blockages or clogs that restrict fuel flow when under load.

- Clean or adjust the carburetor to ensure proper fuel mixture and consistent supply during increased demand.

Have you noticed your generator runs rough whenever you put it under load? If so, you’re not alone. This issue is often linked to problems within the ignition system or fuel delivery, which are crucial for smooth operation. When your generator struggles under load, it’s usually because it’s not firing on all cylinders or isn’t getting the proper fuel flow. Understanding these key components can help you diagnose and fix the problem quickly.

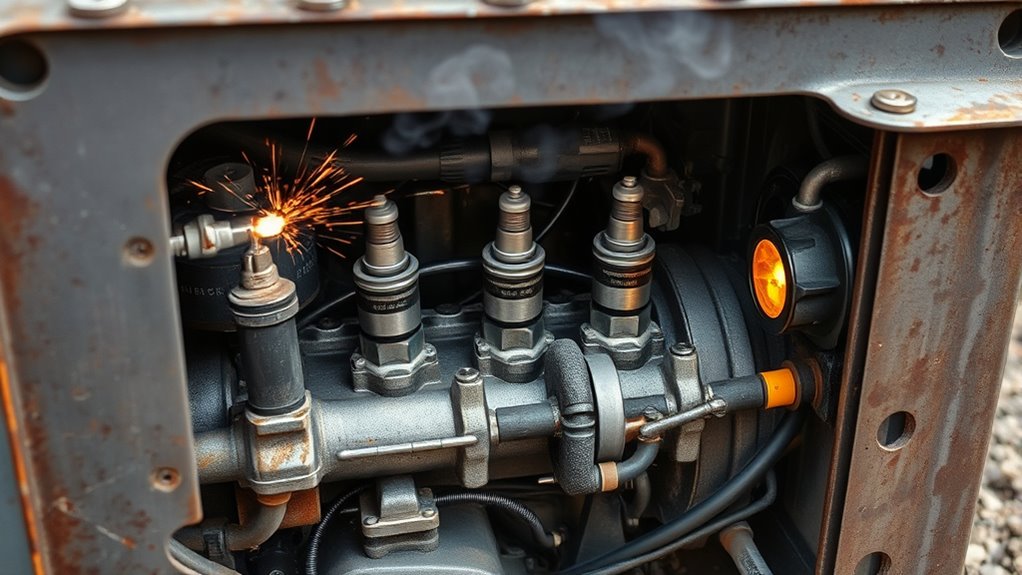

Your ignition system plays a essential role in starting and maintaining the generator’s power. It sparks the combustion process by delivering electrical energy to the spark plug at just the right moment. If the ignition system isn’t functioning properly—say, a worn spark plug, faulty ignition coil, or loose wiring—the spark might be weak or inconsistent. This inconsistency causes misfires, leading to rough operation especially when extra load demands more power. Regular inspection of the spark plug and ignition wires can reveal signs of wear or damage. Replacing a worn spark plug or fixing loose connections often restores proper combustion, smoothing out the generator’s performance.

Regularly inspect and replace worn spark plugs and loose wiring to ensure smooth generator performance.

Fuel delivery is equally important for consistent operation. If your generator isn’t getting a steady supply of clean, properly mixed fuel, it can sputter and run rough under load. Blockages in the fuel line, a clogged fuel filter, or a malfunctioning carburetor can restrict fuel flow. When load increases, these restrictions become more noticeable because the engine struggles to get enough fuel to maintain power. Regularly checking and replacing fuel filters, cleaning the carburetor, and ensuring the fuel tank is clean can prevent these issues. Using fresh, high-quality fuel also reduces the risk of clogging and improves overall fuel delivery.

Sometimes, problems with ignition and fuel delivery are interconnected. For example, a weak spark might lead to incomplete combustion, which in turn affects fuel efficiency and increases deposits in the carburetor. Conversely, poor fuel delivery can cause the engine to misfire, making it seem like an ignition issue. Diagnosing the problem often involves inspecting both systems simultaneously. Testing the spark with a spark tester, checking for proper fuel flow, and observing the engine’s response under load can help pinpoint the root cause. Additionally, ensuring the fuel mixture is correct can improve the generator’s performance under load.

In many cases, simple maintenance fixes—like replacing spark plugs, cleaning the carburetor, or tightening wiring—can resolve rough running issues. If these steps don’t work, it might be time to consult a professional to look deeper into the ignition and fuel systems. Addressing these issues promptly ensures your generator runs smoothly under load, providing reliable power whenever you need it.

Frequently Asked Questions

Can a Faulty Governor Cause Rough Generator Operation?

Yes, a faulty governor can cause rough generator operation. When the governor malfunctions, it disrupts fuel regulation, leading to inconsistent engine speed and rough running under load. You might notice the engine surging or stumbling because it isn’t maintaining proper control over fuel delivery. Checking and repairing the governor guarantees it functions correctly, stabilizing engine performance and preventing rough operation when the generator is under stress.

How Does Altitude Affect Generator Fuel and Spark Performance?

Imagine your generator battling thin mountain air; altitude effects reduce air density, making it harder for fuel to vaporize efficiently. This can cause poor spark performance and incomplete combustion. As you climb higher, you might notice it struggles under load, running rougher. To fix this, you may need to adjust carburetor jets or install altitude compensating devices, helping your generator breathe easier and run smoothly even at higher elevations.

What Role Does Ambient Temperature Play in Generator Issues?

Ambient temperature directly impacts your generator’s cooling efficiency, which can cause rough running under load. When temperatures are too high, the cooling system struggles to dissipate heat, leading to overheating and potential spark or fuel issues. Conversely, cold temperatures can thicken fuel and reduce combustion efficiency. To keep your generator running smoothly, monitor ambient temperature and make certain proper cooling system maintenance, especially in extreme weather conditions.

Are There Specific Signs That Indicate an Impending Generator Failure?

You can spot signs of impending generator failure by paying attention to unusual noises, persistent trouble starting, or frequent overloads. If your generator’s lifespan seems shortened or it requires frequent repairs, it’s time to review your maintenance checklist. Regular inspections and timely maintenance help prevent failures, ensuring your generator runs smoothly under load, especially when you notice performance dips or increased fuel consumption.

How Often Should Routine Maintenance Be Performed to Prevent Rough Running?

Think of your generator like a diva requiring daily pampering. You should follow a strict maintenance schedule, ideally every 50-100 hours of operation or quarterly, whichever comes first. Inspection frequency is key—check spark plugs, fuel lines, and filters regularly. Skipping these checks is like ignoring your diva’s demands, leading to rough running. Keep up with routine maintenance, and your generator will perform smoothly, avoiding dramatic breakdowns.

Conclusion

When your generator runs rough under load, don’t ignore the signs. Spark and fuel issues often hide behind quiet symptoms, waiting to cause bigger problems. By diagnosing these issues early, you keep your power steady and reliable—like a heartbeat in a storm. Remember, a well-tuned generator isn’t just a machine; it’s your silent partner in every blackout. Stay vigilant, stay prepared, and let your generator run smooth as a song.