To check and adjust your generator’s valve clearance, start by ensuring the engine is cool. Remove the valve cover and use a feeler gauge to measure the gap between the valve and rocker arm. If the clearance isn’t correct, loosen the adjustment screw and set it to the specified gap, then tighten it securely. Properly adjusted valves help maintain engine efficiency and lifespan, and you’ll discover more tips if you keep exploring this topic further.

Key Takeaways

- Consult the manufacturer’s manual for specific valve clearance specifications and procedures.

- Use a feeler gauge to measure the valve gap when the engine is cold or at recommended timing.

- Loosen the adjustment screw and set the correct clearance by tightening or loosening as needed.

- Rotate the engine manually to ensure valves are fully closed before measuring or adjusting.

- Recheck the clearance after adjustment, ensure components are secure, and record maintenance for future reference.

Have you ever wondered why maintaining proper valve clearance is essential for your generator’s performance? The answer lies in the critical role valve clearance plays in ensuring your engine runs smoothly and efficiently. When valve clearance is off, it can adversely affect valve timing, leading to poor combustion, reduced power output, and increased wear on engine components. Regularly checking and adjusting this clearance helps keep your generator operating at peak performance and extends its lifespan.

Valve timing is directly influenced by the clearance between the valve and the rocker arm or camshaft. If the clearance is too tight, the valves may not fully close, causing misfires and incomplete combustion. Conversely, if the clearance is too loose, it can result in noisy operation, excessive wear, and inefficient valve operation. These issues emphasize why understanding and maintaining proper valve clearance is vital. To avoid these problems, you should incorporate valve clearance checks into your maintenance schedule, ideally at regular intervals recommended by your generator manufacturer. This schedule typically varies based on usage hours and operating conditions but generally involves inspecting the clearance every few hundred hours of operation.

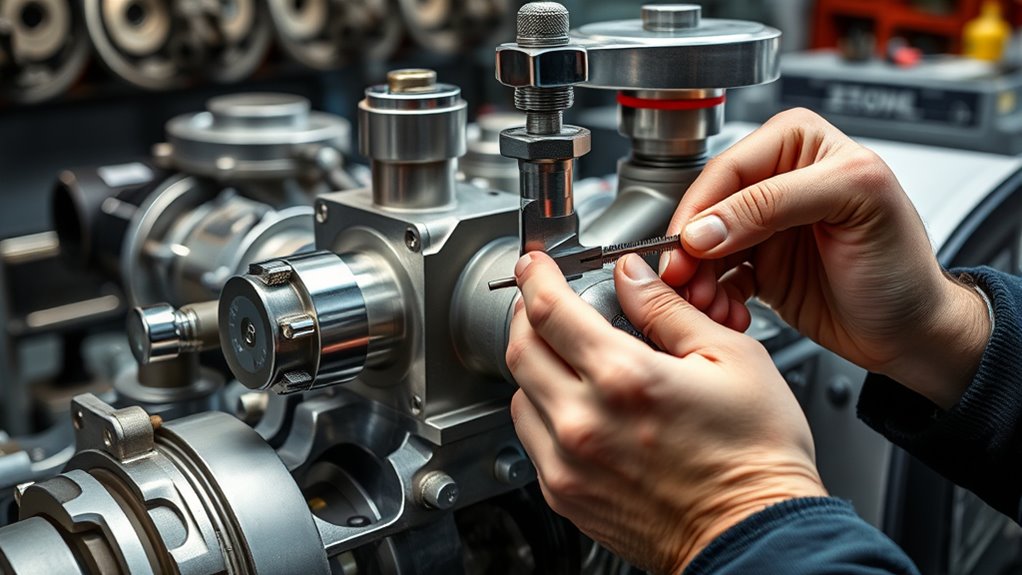

Following a consistent maintenance schedule ensures you catch potential issues early before they escalate into costly repairs. When you perform these checks, you’ll need to measure the gap between the valve stem and the rocker arm or camshaft using a feeler gauge. If the clearance isn’t within the specified range, you’ll need to adjust it by tightening or loosening the adjustment screw. Doing this correctly requires attention to detail, patience, and a basic understanding of your generator’s valve system. Proper adjustment restores ideal valve timing, which is essential for efficient engine operation. Additionally, understanding the importance of regular candy maintenance can help prevent issues related to neglect or improper adjustments.

Frequently Asked Questions

How Often Should Valve Clearance Be Checked on a Generator?

You should check your generator’s valve clearance according to the valve clearance schedule, typically every 100-200 hours of operation or once a year, whichever comes first. Regular maintenance tips include inspecting for signs of wear and ensuring proper clearance to prevent engine damage. Staying consistent with these checks helps keep your generator running smoothly and extends its lifespan. Always refer to your manufacturer’s manual for specific intervals and procedures.

Can Valve Clearance Adjustments Improve Generator Performance?

Yes, adjusting valve clearance can substantially improve your generator’s performance. When valves are properly set, you’ll notice less valve noise and smoother operation. This fine-tuning can also boost fuel efficiency, saving you money over time. Don’t ignore these adjustments, as they help prevent engine wear and maintain ideal power output. Keeping your valves correctly adjusted ensures your generator runs reliably and efficiently, giving you peace of mind during critical times.

What Tools Are Necessary for Adjusting Valve Clearance?

To adjust valve clearance during generator maintenance, you’ll need specific valve adjustment tools like a feeler gauge, wrench set, and possibly a screwdriver. These tools help you measure and set the correct clearance precisely. Having the right valve adjustment tools guarantees you can perform maintenance efficiently and accurately, preventing engine issues and improving performance. Always double-check your tools and follow the generator manufacturer’s specifications for ideal results.

Are There Safety Precautions Before Starting Valve Adjustments?

Think of safety as your trusty shield before you begin. You should follow safety protocols by disconnecting the power, ensuring the engine is cool, and using protective gear like gloves and eye protection. These precautions act as your safety net, preventing accidents and injuries. Always double-check your safety measures, because a cautious approach keeps you safe and your work efficient while adjusting valve clearance.

How Do Temperature Changes Affect Valve Clearance Settings?

Temperature changes cause thermal expansion, which affects valve clearance settings. As engine parts heat up, metal expands, potentially increasing clearance and altering valve timing. To guarantee proper operation, you should measure valve clearance when the engine is at its normal operating temperature or follow manufacturer guidelines for cold or hot adjustments. This helps maintain ideal valve timing and prevents engine damage caused by incorrect clearance.

Conclusion

As you finish checking and adjusting the valve clearance, imagine the engine’s heart beating in perfect harmony, each valve opening and closing like a well-rehearsed dance. With your hands steady and your mind focused, you’ve tuned the symphony of metal and motion, ensuring smooth operation. Now, as the engine roars back to life, feel the satisfaction of a job well done—knowing you’ve kept this essential heartbeat steady, ready to power through many more miles ahead.