Before you start, identify whether your system has a bonded or floating neutral, as this affects your maintenance steps. For bonded neutrals, verify the neutral is correctly connected to the grounding system and check for secure, corrosion-free connections. For floating neutrals, ensure the neutral remains isolated from ground. Always wear proper safety gear and follow safety protocols. Continuing guarantees you understand specific inspection and safety measures tailored to each system type.

Key Takeaways

- Verify whether the system has a bonded or floating neutral to determine proper inspection procedures.

- Ensure all grounding connections are secure, compliant, and free of corrosion or damage.

- Confirm neutral is properly bonded to ground in bonded systems; isolate neutral in floating systems.

- Use appropriate personal protective equipment and follow safety protocols during inspection.

- Regularly check for loose, damaged, or corroded connections to maintain system safety and reliability.

Understanding the Basic Differences Between Bonded and Floating Neutrals

Understanding the basic differences between bonded neutrals and floating neutrals is essential for maintaining electrical system safety and performance. Bonded neutrals connect the neutral to ground at the main panel, creating a direct grounding path and stabilizing voltage levels. In contrast, floating neutrals are isolated from ground, which can prevent ground fault currents from flowing back through the system. Grounding differences considerably impact system behavior and fault detection. Bonded neutrals help ensure safety by providing a reliable reference point, but they can also increase the risk of shock if not properly maintained. Floating neutrals reduce certain shock hazards but may cause voltage fluctuations and equipment malfunction. Recognizing these system implications allows you to choose the right configuration and maintain your electrical system effectively. Additionally, understanding entertainment and parks operating hours can be helpful when planning visits to recreational locations near electrical installations or maintenance sites to ensure safety and convenience.

Essential Safety Precautions and Inspection Steps for Each System

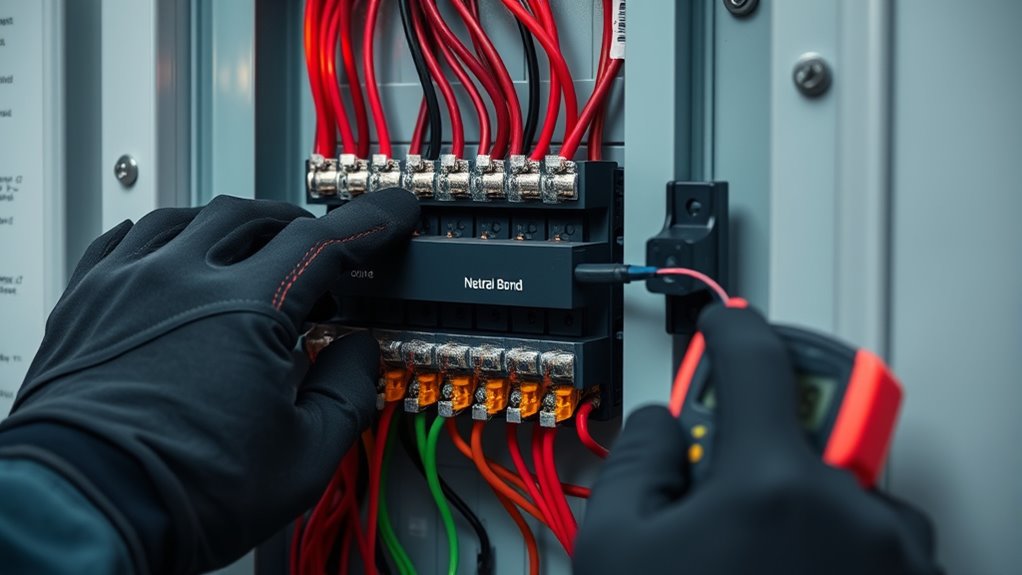

When working with bonded or floating neutral systems, safety should always come first, and proper inspection steps are critical to prevent accidents. Confirm grounding requirements are met, as proper grounding reduces shock risk and helps with fault detection. Check that all grounding connections are secure and compliant with electrical codes. For bonded systems, verify that the neutral is properly bonded to the grounding system to facilitate fault detection. In floating neutral systems, affirm that the neutral remains isolated to avoid unintended current paths. Regularly inspect for signs of corrosion, loose connections, or damage that could compromise safety or system performance. Always use appropriate personal protective equipment and follow established safety protocols. Proper inspection minimizes hazards and ensures reliable operation of both bonded and floating neutral systems. Additionally, understanding AI in Business can help identify opportunities to enhance safety protocols through automation and real-time monitoring.

Frequently Asked Questions

How Often Should Bonded and Floating Neutral Systems Be Inspected?

You should inspect bonded and floating neutral systems at least annually to guarantee grounding safety and prevent electrical hazards. Regular inspections help identify loose connections, corrosion, or damage that could compromise system integrity. If you notice any issues, address them promptly to maintain safe operation. In environments with frequent environmental changes or heavy usage, consider more frequent checks to protect against potential electrical hazards and ensure grounding safety.

What Tools Are Necessary for Neutral System Testing and Maintenance?

Your toolkit for neutral system testing and maintenance is your secret weapon against electrical chaos. You’ll need a multimeter to perform testing procedures, checking for proper grounding and voltage levels. Insulated screwdrivers ensure safety precautions are met when working with live components. A clamp meter helps measure current, and a continuity tester verifies connections. Always wear safety gear, follow procedures carefully, and double-check your tools before starting to prevent hazardous surprises.

Are There Specific Signs Indicating Neutral System Faults or Failures?

You should watch for neutral fault indicators like flickering lights, unexpected voltage fluctuations, or persistent electrical shocks. These signs suggest a neutral system fault or failure. Always prioritize system safety considerations by turning off power and testing with proper tools before inspection. Addressing these issues promptly helps prevent equipment damage and electrical hazards, ensuring safe and reliable operation of your electrical system.

Can Homeowners Perform Neutral Maintenance Tasks Safely?

Thinking about neutral maintenance is like walking a tightrope—you need to stay careful. While some tasks, like inspecting grounding issues or conducting insulation testing, seem manageable, it’s safest to leave complex work to professionals. If you notice signs of grounding issues or suspect neutral faults, avoid DIY fixes. Always turn off power first, use proper tools, and when in doubt, call an electrician to prevent hazards and guarantee your home’s electrical safety.

What Are the Common Mistakes to Avoid During Neutral System Inspections?

When inspecting your neutral system, avoid mistakes like neglecting to verify proper grounding or skipping electrical safety protocols. Don’t assume everything is fine without testing connections thoroughly, as loose or corroded neutral wires can cause safety hazards. Guarantee grounding is secure and follow safety protocols diligently to prevent shocks or damage. Regularly check for signs of wear, and always turn off power before inspecting to keep yourself safe.

Conclusion

Now that you understand the differences between bonded and floating neutrals, picture yourself as the guardian of your electrical system’s safety. Regular inspections are like tending a garden—you catch issues early before they grow wild. With your vigilant eye, you ensure the currents flow smoothly, keeping your home safe and secure. Remember, a little maintenance now prevents a storm of problems later, so stay proactive and keep that electrical harmony alive.